QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

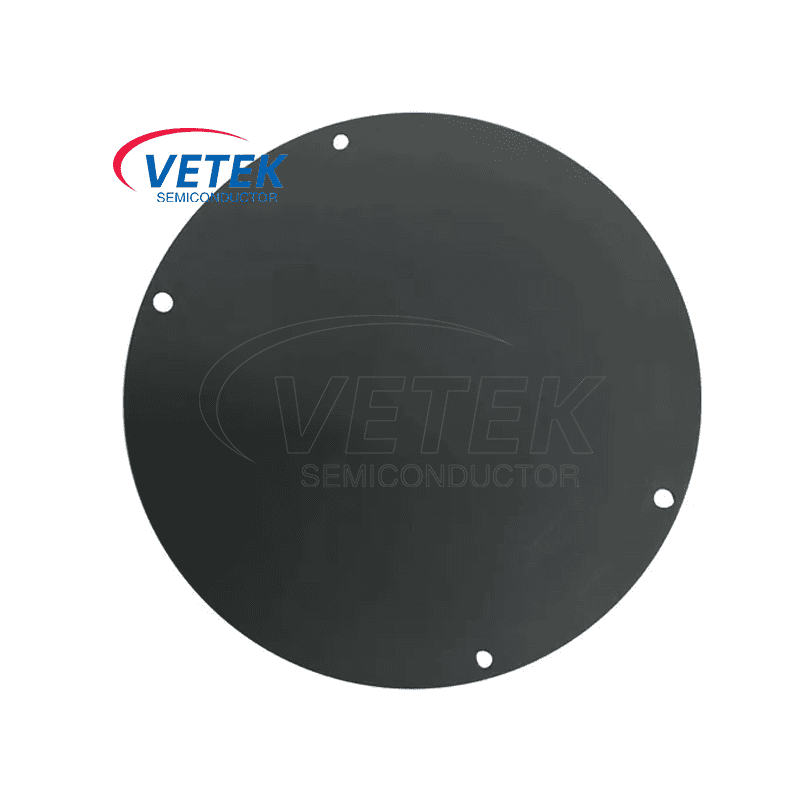

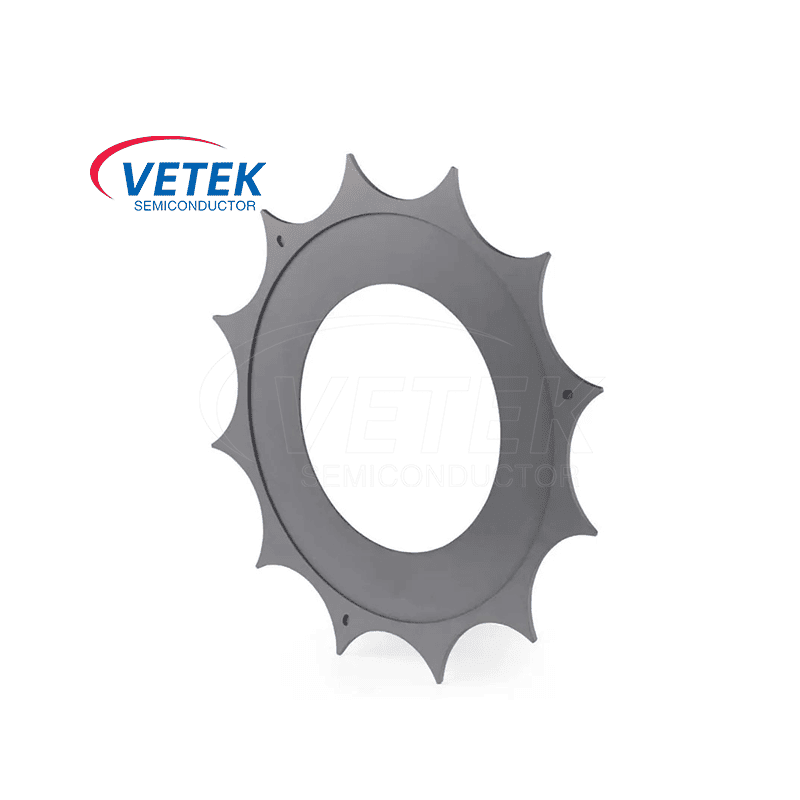

VeTek Semiconductor speciale in productione ultra purum Siliconis Carbide productorum Coating, hae tunicae ad graphites, ceramicos et metalla refractoria applicanda destinantur.

Nostrae puritatis altae coatinges praesertim in usu in semiconductoribus et in industriis electronicis iaculis sunt. Pro tutelae laganum baiulum, susceptores et elementa calefacientia inserviunt, ea custodiendo a ambitus mordax et reactiva, quae in processibus occurrunt, ut MOCVD et EPI. Hi processus integrales sunt processus lagani et fabrica fabricandi. Accedit, nostrae membranae aptae sunt applicationibus in fornacibus vacuo et calefactione exempli, ubi summus vacuum, reactivum et oxygenii ambitus offendit.

In VeTek Semiconductor, solutionem comprehensivam offerimus cum facultatibus machinarum machinarum provectorum. Hoc efficit ut basium componentium utentes graphite, ceramico, vel refractariis metallis fabricare, ac ceramicam SiC vel TaC coatings in aedibus adhibere possimus. Etiam operas efficiens praebemus ad partes suppeditatas, ut flexibilitas ad diversas necessitates occurrat.

Nostri Silicon Carbide Productorum Coating late usi sunt in epitaxy Si, epitaxy SiC, systema MOCVD, RTP/RTA processus, processus engraving, processus ICP/PSS engraving, processus variarum LED generum, inter caeruleum et viridem LED, UV LED et profunde UV DUXERIT etc., quod aptatur instrumentis ex LPE, Aixtron, Veeco, Nuflare, TEL, ASM, Annealsys, TSI et sic porro.

| Basicae physicae proprietates CVD SiC coating | |

| Property | Typical Value |

| Crystal Structure | FCC β Phase polycrystallina, maxime (111) ordinatur |

| Sic coating densitas | 3.21 g/cm³ |

| Sic coatingHardness | MMD Vickers duritiem 500g onus |

| Frumenti amplitudo | 2~10μm |

| Puritas chemica | 99.99995% |

| Calor Capacity | 640 J·kg-1·K-1 |

| Sublimatio Temperature | 2700℃ |

| Flexurae Fortitudo | 415 MPa RT 4-punctum |

| Modulus | 430 Gpa 4pt bend, 1300℃ |

| Scelerisque Conductivity | 300W·m-1·K-1 |

| Scelerisque Expansion (CTE) | 4.5×10-6K-1 |

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |