QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

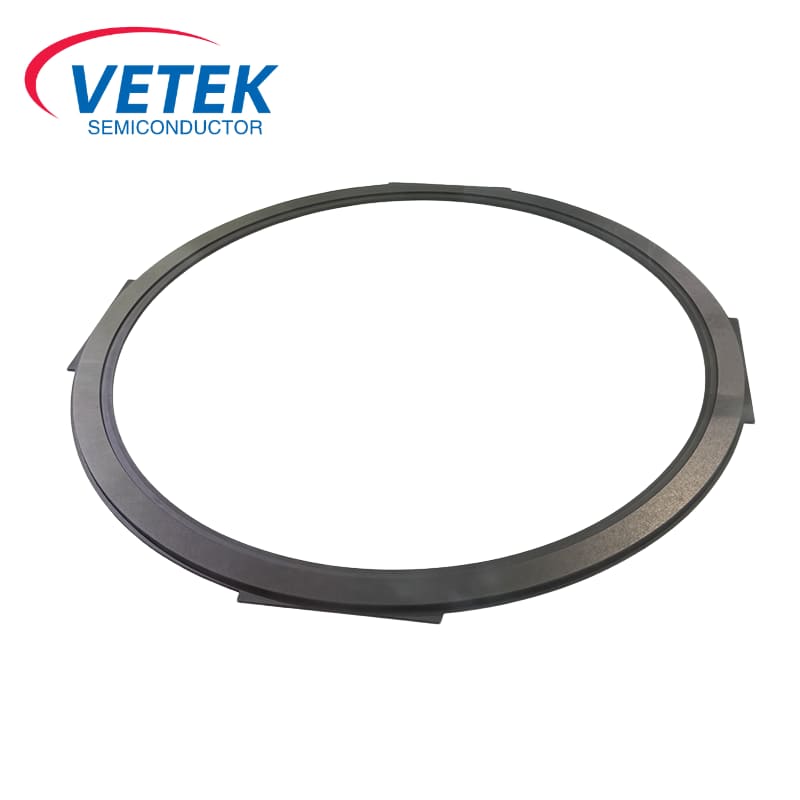

Vetek semiconductor solidum Silicon carbide est momenti tellus component in Plasma Etching Equipment, solidum Silicon Carbide (CVD Silicon Carbide) Partibus in Etching apparatu includitfocusing annulos, Gas showhead, Tray, Edge Annulorum, etc Ob ad humilis Reactivity et conductivity solidum Silicon Carbide (CVD Silicon Carbide) ad CHLORUM - et Plasma Plasma Etching Equipment Focusing Annulorum et aliarum components.

Exempli gratia, in focus anulus est momenti pars positus extra laganum et in directum contactus cum laganum, per applicando ad anulum ad focus in plasma transiens per anulum, ita focusing ad plasma in laganum ad amplio in dispensando. Traditional Focus anulus factum est de Silicon autquartz, PROLIXUS Silicon ut communis focus anulum materia, quod est fere prope ad conductivity Silicon Wafers, sed penuria est pauper etching resistentia in fluorine, continens Plasma, etching apparatus partibus, ut saepe usus est ad tempus, ibi erit gravis productionis.

Solid sic focus circulumOpus:

Et secundum collatio Focusing circulum et CVD sic focusing circulum:

| Compare de Si fundatur focusing circulum et cvd sic focusing circulum | ||

| Item | Et | Cvd sic |

| Density (g / cm3) | 2.33 | 3.21 |

| Cohors Gap (Ev) | 1.12 | 2.3 |

| Thermal conductivity (W / cm ℃) | 1.5 | 5 |

| CTE (X10-6/ ℃) | 2.6 | 4 |

| Elastica modulus (GPA) | 150 | 440 |

| Durness (GPA) | 11.4 | 24.5 |

| Resistentia ad induendum et corrosio | Pauper | Praeclarus |

Vetek semiconductor offert provectus solidum Silicon Carbide (CVD Silicon Carbide) partibus quasi sic focusing annulos ad semiconductor apparatu. Nostra solida Silicon carbide focusing annulos outperform traditional Silicon in terms of mechanica vires, eget resistentia, scelerisque conductivity, summus temperatus diuturnitatem, et Ion etching resistentia.

Maximum density ad reducitur etching rates.

Optimum Valerius cum summus bandgap.

High scelerisque conductivity et humilis coefficiens de scelerisque expansion.

Mechanica impulsum resistentia et elasticitas.

High duritia, gerunt resistentia, et corrosio resistentia.

Usura fabricaPlasma-amplificata eget vapor depositione (Pecvd)Techniques, nostri sic focusing annulos occursum augendae postulat etching processus in semiconductor vestibulum. Sunt disposito resistere altius plasma virtutis industria, specie inCapacitaliter coniungar Plasma (CCP)systems.

Vetek Semiconductor est Sic Porcek Annulorum providere eximia perficientur et reliability in semiconductor fabrica fabrica. Elige nostrum sic partes pro superior species et efficientiam.

Veteksemicon solid silicon carbide is the ideal procurement material for high-temperature, high-strength, and corrosion-resistant components used in semiconductor and industrial applications. As a fully dense, monolithic ceramic, solid silicon carbide (SiC) offers unmatched mechanical rigidity, extreme thermal conductivity, and exceptional chemical durability in harsh processing environments. Veteksemicon’s solid SiC is specifically developed for critical structural applications such as SiC wafer carriers, cantilever paddles, susceptors, and showerheads in semiconductor equipment.

Manufactured through pressureless sintering or reaction bonding, our solid silicon carbide parts exhibit excellent wear resistance and thermal shock performance, even at temperatures above 1600°C. These properties make solid SiC the preferred material for CVD/PECVD systems, diffusion furnaces, and oxidation furnaces, where long-term thermal stability and purity are essential.

Veteksemicon also offers custom-machined SiC parts, enabling tight dimensional tolerances, high surface quality, and application-specific geometries. Additionally, solid SiC is non-reactive in both oxidizing and reducing atmospheres, enhancing its suitability for plasma, vacuum, and corrosive gas environments.

To explore our full range of solid silicon carbide components and discuss your project specifications, please visit the Veteksemicon product detail page or contact us for technical support and quotations.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |