QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Sic wafer carriers, Sicut clavis per consumables in tertia-generationem semiconductor industria catholos, technica proprietates directe afficiunt cede epitaxial incrementum et fabrica vestibulum. Cum enim aegri demanda summus intentione et summus temperatus cogitationes in industries ut 5G basi stationibus et novi industria vehicles, in investigationis et applicationem de sic lagam vehicles sunt nunc adversus significant progressionem occasiones.

In agro Semiconductor vestibulum, Silicon Carbide Wafer deformes maxime suscipere momenti munus portandi et transmittendi wafers in epitaxial apparatu. Comparari cum traditional quartz carriers, sic carriers exhibent tria core commoda: Uno modo, in coefficientem de scelerisque expansion (4.0 × X ^ -6 / ℃), efficaciter reducendo -6 (℃), efficaciter reducendo -6 (℃), efficaciter reducendo, in sic -6 / ℃ 4.2 processus reducing -6 / ℃), efficaciter reducendo -6 (℃), efficaciter reducendo in sic -6 / ℃ 4.2 processus reducing -6 / ℃), efficaciter reducendo, in sic -6 (℃ 4.2 processus reducing -6 / ℃), efficaciter reducendo scelerisque accentus in altum temperatus processibus; Secundo puritate summus puritatis sic carriers paratus a eget vapor depositione (cvd) modum potest pervenire 99,9995%, avoiding communi sodium ion contamination forsit de Quartz carriers. Ceterum in liquescens punctum in sic materia ad MMDCCCXXX ℃ dat eam ad aptet ad diu-term operantes environment supra MDC ℃ in Mocvd apparatu.

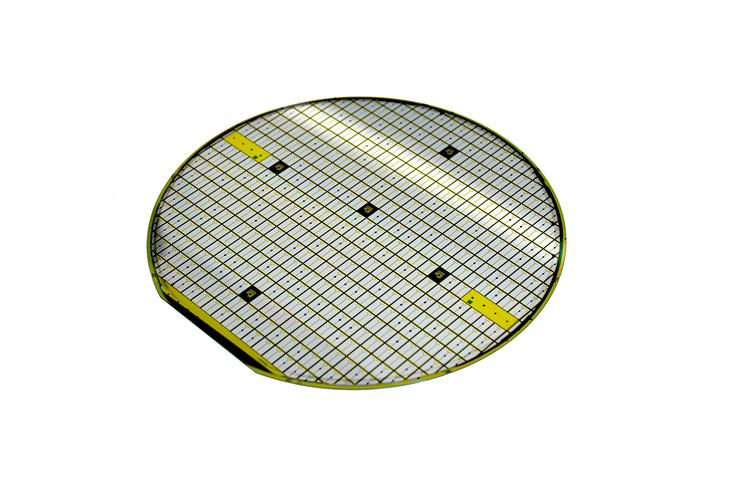

In praesenti, in amet products adopt a VI-inch speciem, cum crassitudine imperium in range of 20-30mm et superficiem asperitas postulationem minus quam 0.5μm. Ad augendae epitaxial uniformitatem, ducens manufacturers construxit specifica topological structuras in carrier superficiem per Cnnkining. Nam exempli gratia, in favum-informibus sulcus Design developed per semiceri potest control crassitiem fluctuationem de epitaxial layer in ± III%. Technology in verbis, Tac / Tasi2 Compositum coating extend in ministerium vitae carrier super DCCC temporibus, quae ter longior quam ut examinaretur uber.

In Industrial Application gradu, sic carriers paulatim per totam vestibulum processus Silicon carbide potentia cogitationes. In productio de SBD Diodes, usum Sic carriers potest reducere epitaxial defectus density ad minus quam 0.5cm ². Nam Mosfet cogitationes, eorum optimum temperatus uniformitatem adjuvat ad augendam alveo mobilitatem per XV% ad XX%. Secundum ad industriam statistics, in global Sic carrier foro mole exceditur CCXXX decies pupa in MMXXIV, cum compositis annua incrementum rate ad circum XXVIII%.

Tamen, technica bottlenecks adhuc est. In Word Imperium magnam, amplitudo carriers manet a provocatione - in planities tolerantia VIII-inch portarentur necessitates ad inter 50μm. In praesenti, semicera est unum ex paucis domesticis societates quae potest control warping. Domesticis conatibus ut Tianke heda habere effectum massa productionem VI-inch portarentur. Servi est currently assistentes Tianke Heda in Customizing Sic carriers pro illis. In praesens, quod est accederent internationalis gigantes in terms of coating processus et defectus imperium. In futuro, cum maturitatem heroepitaxy technology, dedicated carriers ad Gan-in-sic applications erit novam investigationis et progressionem directionem.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |