QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

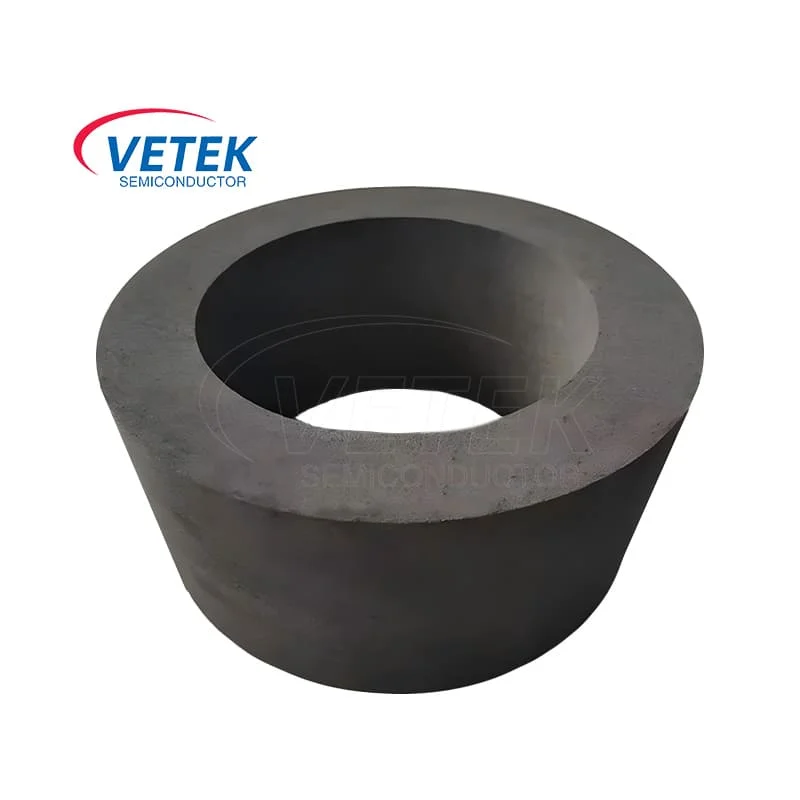

SIC subiectis effectrix communiter utor a crudible consilio cum raro graphite cylindri ad calidum agro processus. Design auget evaporation area et crimen volumine. Novum processus est developed to oratio crystal defectus, stabiliendum missa translatio, et augendae sic crystal qualitas. Hoc incorporat et seedless cristallum lance fixation modum ad scelerisque expansion et accentus relevium. Autem, limitata foro copia cruciatum graphite et raro graphite opposuit challenges ad qualis et cedat ex Sic una crystallis.

1.High Tortatus environment tolerantia - quod productum potest resistere elit MMD gradus Celsius, demonstrando optimum æstus resistentia.

2.Strict Porosity Control - Vetek Semiconductor maintains stricta Porosity control, cursus consistent perficientur.

3.ULRA-excelsum puritatis - et Porae Graphite materia usus est summus gradu puritatis per rigorous Purification processibus.

4.excellent superficiem particula binding - Vetisk Semiconductor est optimum superficiem particula binding facultatem et resistentia ad pulveris adhaesionem.

5.Gas onerariam, diffusio, et uniformitatem - et raro structura Graphite facilitatem agentibus Gas onerariam et diffusionem, unde in melius uniformitatem gasorum et particulas.

6.Quaquality Control et stabilitatem - Vetek Semiconductor extollit summus puritas, humilis immunditia contentus, et eget stabilitatem ad curare qualitas in crystallum incrementum.

7.Tempature Imperium et uniformitatem - The Conductivity De Pororo Graphite dat uniformis temperatus distribution, reducendo accentus et defectus per incrementum.

8.Enhanced solute diffusio et incrementum rate - quod raro structuram promovet etiam solute distribution, enhancing incrementum rate et uniformitatem crystallis.

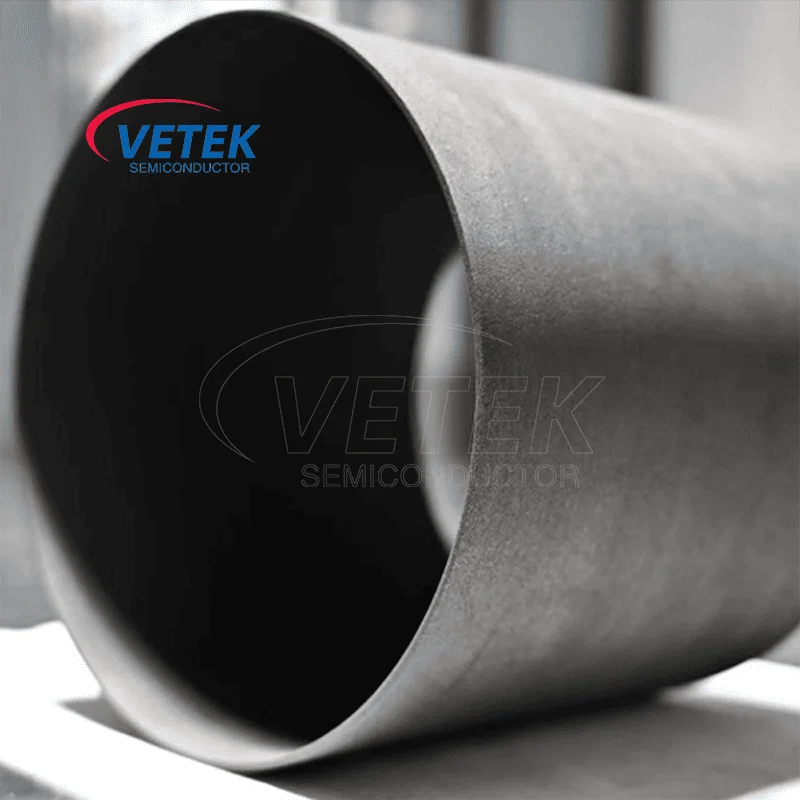

Veteksemicon porous graphite materials are your ideal procurement choice for precision thermal processing and vacuum applications. With high porosity, uniform pore distribution, and excellent chemical resistance, Veteksemicon's porous graphite is engineered to meet the strict demands of advanced semiconductor manufacturing, filtration systems, and fuel cell components. These materials enable efficient gas diffusion, fluid flow control, and thermal management, making them indispensable in processes like vacuum chucks, electrochemical applications, and battery electrodes.

Each porous graphite block or plate is manufactured using advanced graphite molding and sintering techniques, ensuring optimal performance in high-temperature and corrosive environments. Due to its open-cell microstructure and customizable pore size, our porous graphite offers superior permeability and thermal conductivity while maintaining dimensional stability under extreme conditions.

This category also covers related entities such as graphite vacuum plates, porous graphite discs, frequently used in semiconductor wafer handling and energy systems.

Discover more product details on Veteksemicon's Porous Graphite product page or contact us for technical specifications and custom solutions.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |