QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Under the Silicon Carbide Coating category, the 'Other Process' section features advanced components such as Graphite Heating Units, Hot Zone Graphite Heaters, and Silicon Carbide Wafer Chucks. These parts are vital in high-temperature, vacuum, and plasma environments in semiconductor fabrication.

Graphite-based heaters with SiC coatings offer excellent thermal stability, oxidation resistance, and uniform heat distribution, ensuring long service life and process consistency in epitaxy, diffusion, and CVD processes. They are key to maintaining precise thermal control.

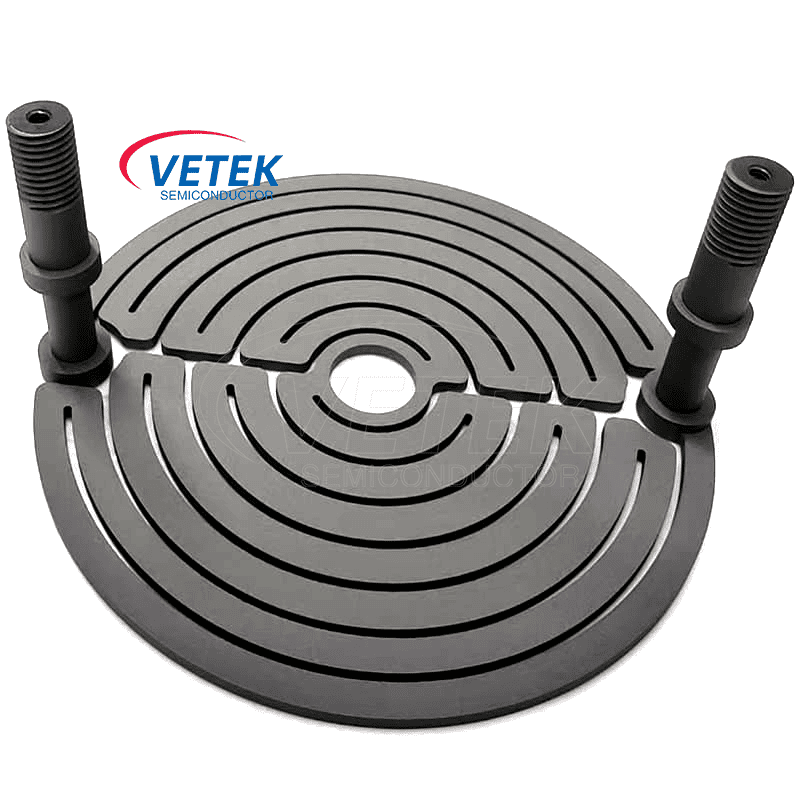

Silicon Carbide Wafer Chucks and standard Wafer Chucks are designed to securely hold wafers during thermal and plasma processing. Their high rigidity, chemical inertness, and thermal shock resistance make them ideal for next-generation semiconductor manufacturing.

The 'Other Process' product line reflects VeTek Semicon’s commitment to delivering durable, high-performance SiC-coated components that withstand harsh process conditions while improving system efficiency, reducing particle contamination, and enhancing overall yield.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |