QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Vetek Semiconductor est ducens manufacturer de Porous sic Ceramics ad semiconductor industria. Transierunt ISO9001, Vetek Semiconductor habet bonum imperium in qualis. Vetec Semiconductor semper committitur ad decet in innovator et ducem in raro sic Ceramic industria.

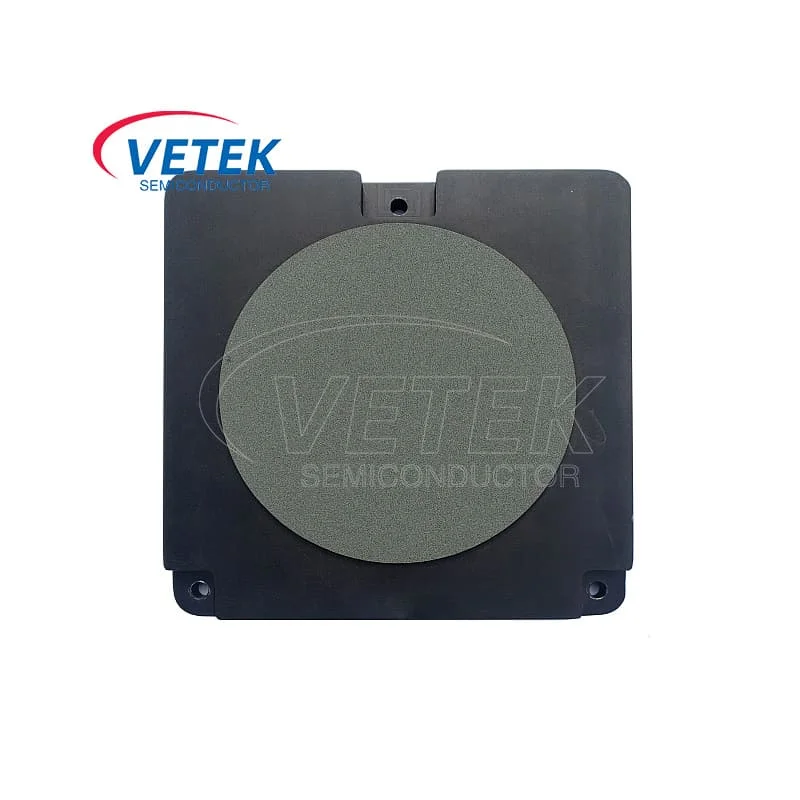

Pororem Sic Ceramic Disc

Pororus Sic Ceramics sunt Ceramic materia, quae sunt accensus ad altum temperaturis et habere magnum numerum internonectected aut clausa poros intus. Est etiam notum est ut microporous vacuum suctionem calicem, cum pore moles vndique a II ad 100um.

Pororem Sic Ceramics late in metallurgy, eget industria, environmental tutela, biology, semiconductor et aliis agris. Purore Sic Ceramics potest parari per spumans modum, Sol gel modum, tape mittens modum, solidum peccare modum et impregnation Pyrolysis modum.

Praeparatio Puvent SIC Ceramics per Sinctering modunus

Proprietatibus raro Silicon carbide LATERAMEN paravit per diversas modos in function of poros

![]()

Purore Sic Ceramics Suction pocula in Semiconductor laganace

Vetek Semiconductor est Poruus Sic Ceramics Play in Partes in Clamping et portantes wafers in semiconductor productio. Sunt densa et uniformis, princeps in viribus, bonum in aere permeability et uniformis in adsorption.

Et efficaciter address tot difficile problems ut laganum incisum et chip electrostatic naufragii et auxilium consequi processus maxime summus qualitas wafers.

Working Diagram de Puvens Sic Ceramics:

Opus principium de raro Sic Ceramics: et Silicon Wafer sit certa a vacuo adsorption principle. Per dispensando, in parva foramina in raro sic Ceramics sunt ad eliciunt caeli inter Silicon laga et Ceramic superficiem, ut Silicon lana et Ceramic superficiem sunt ad humilis pressura, ita fixing Silicon laga.

Post dispensando, plasma aquam fluit ex foraminibus ne Silicon laganum a adhaerens ad Ceramic superficiem simul et Silicon laga et Ceramic superficiem purgari.

Microstucture de raro sic Ceramics

Highlight commoda et features:

● High Temperature Resistance

● resistentia ad induendunus

● chemical resistentia

● High mechanica vires

● Securus ad regenerare

● optimum scelerisque inpulsa resistentia

item

unitas

Pororus Sic Ceramics

PORE

unus

X ~ XXX

Densitas

G / CM3

1.2 ~ 1.3

Superficiem rougcalumnia

unus

2.5 ~ III

Aeris effusio valorem

Kpa

-45

Flacalis fortitudinem

MPA

30 Dielectric constant

1MHz

33 Scelerisque conductivity

W / (m k)

LX ~ LXX

Plures alta requisita raro Sic Ceramics:

I. fortis vacuo adsorption

II. Plances est valde magna, aliter non erit problems per operationem

III. Non deformatio et non metallum impudicitiis

Ideo in aerem effusio valorem de Veteec Semiconductor scriptor Porobus Sic Ceramics ad -45kpa. Simul sunt temperari MCC ℃ 1.5 horas antequam officinas removere impudicitiis et packaged in vacuo sacculos.

Pororem Sic Ceramics late in lagoenas in lagoenas processus technology, transferre et alia links. Et fecerunt magnas res gestae in vinculum, Dorming, adscendens, politant et alia links.

Order precision-engineered Porous SiC ceramics from Veteksemicon—ideal for thermal uniformity and gas control in semiconductor systems.

Veteksemicon’s porous silicon carbide (SiC) components are engineered for high-temperature plasma processes and advanced gas flow control. Ideal for PECVD, ALD, vacuum chucks, and gas distribution plates (showerheads), these components offer excellent thermal conductivity, thermal shock resistance, and chemical stability.

Our porous SiC features a controlled pore structure for consistent gas permeability and uniform temperature distribution, reducing defect rates and enhancing yield. It is widely used in wafer handling platforms, temperature equalizing plates, and vacuum holding systems. The material ensures mechanical durability under corrosive and high-load thermal conditions.

Contact Veteksemicon today to request custom Porous SiC solutions or detailed engineering parameters.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |