QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Silicon carbide subiectis habent plures defectus et non potest processionaliter directe. A specifica unum crystallum tenuis film necessitates ad crevit in eos per epitaxial processus ut chip wafers. Haec tenuis film est epitaxial layer. Fere omnes Silicon carbide cogitationes sunt, intellexit in epitaxial materiae. High-species Silicon Carbide Homogenea epitaxial materiae sunt basis pro progressionem de Silicon carbide cogitationes. In perficientur epitaxial materiae directe determinat realization de perficientur de Silicon carbide cogitationes.

High-vena et summus reliability Silicon carbide cogitationes et posuit deinceps plus restrictius requisitis in superficiem Insecta, defectus density, doping et crassitudine uniformitatem epitaxial materiae. Magnam magnitudine humilis defectus density et summus uniformitatemSilicon carbide epitaxyfacta est clavis ad progressionem de Silicon carbide industria.

Praeparatio summus qualitasSilicon carbide epitaxyrequirit provectus processus et apparatu. Maxime late usus Silicon carbide epitaxial incrementum modum est eget vapor depositione (CVD), quae habet commoda precise imperium epitaxial film crassitudine et doping concentration, paucioribus defectus, moderate incrementum rate, paucioribus, moderari incrementum rate, paucioribus, modica incrementum rate, paucioribus, modica incrementum, et automatic processus imperium. Est certa technology quod iam prospere commercialized.

Silicon Carbide CVD epitaxy plerumque utitur calidum murum vel calidum murum cvd apparatu, quod ensures continuatio de epitaxial layer 4h Crystalli SIC in altioribus incrementum temperatus conditionibus (1500-1700 ℃). Post annos progressionem calidum murum calidum murum cvd potest dividi in horizontalem structuram reactores et vertical vertical structuram reactors secundum necessitudinem inter directionem directionem directionem in incolis Gas fluxus et subiectum superficiem.

Et qualis est Silicon carbide epitaxial fornacem maxime habeat tres Indicatores. Primum est epitaxial incrementum perficientur, inter crassitudine uniformitatem, doping uniformitatem, defectum rate et incrementum rate; Secundum est temperatus perficientur in apparatu se, comprehendo calefactio / refrigerationem rate, maximum temperatus, temperies uniformitatem; Et postremo ad sumptus perficientur in apparatu ipsum, comprehendo unit pretium et productionem facultatem.

Calidum Wall Horizontalis CVD, calidum Wall Planetary CVD et quasi-calidum murum vertical CVD sunt amet epitaxial apparatu technology solutiones quae commercium applicari in hoc gradu. Tria technica apparatu etiam proprietates potest electus secundum necessitates. In structuram tabula est ostensum est in figura infra:

Et calidum murum horizontalis CVD ratio plerumque unum-laganum magnam magnitudinem incrementum ratio repulsi aerem flotation et gyrationis. Facile ad consequi bonum in-laganum Indicatores. Repraesentativas exemplar pe1o6 LPPe turma Italiae. Hoc apparatus can animadverto automatic loading et unloading de wafers at CM ℃. Et pelagus features sunt princeps augmentum rate, brevi epitaxial cycle, bonum constantia intra lagam et inter Furnaces, etc habet summa foro participes in Sinis.

Secundum LPE publica tradit, combined cum usus est Maior users, in 100-150mm (4-6 digitos), in SIC EPITAAXIUS PE1O6 cum in crassitudine non-ciuform steaced in Pe1o6 in sequentibus Indicatores non-uniformitatem%, intra-lawfer doping non-uniformitatem non-uniformitatem ≤5%: Superficiem defectum density ≤1cm-II, superficies defectum-liberum area (2mm × 2mm unit cell) ≥90%.

Domesticis turmas ut JSG, CETC XLVIII, Nuraura et Naso Developed Monolithic Silicon carbide epitaxial apparatu cum similia munera et effectum magnum-scale portarentur. Exempli gratia, in February MMXXIII, JSG dimisit a VI inch duplici-lagest sic epitaxial apparatu. Apparatu utitur superioris et inferioribus stratis superioris et inferioris stratis graphite partes reactionem germinare duo epitaxial in uno camili, et superius et inferioris ≤5 ° C, quod efficaciter facit ad incommodum et inferior productionem facultatem ad monolitotimentorum, cum in incommodum est in MonolithSic partibus membrana coating Halfmoon.We sunt supplementum VI inch et VIII inch helfmoon partibus ad users.

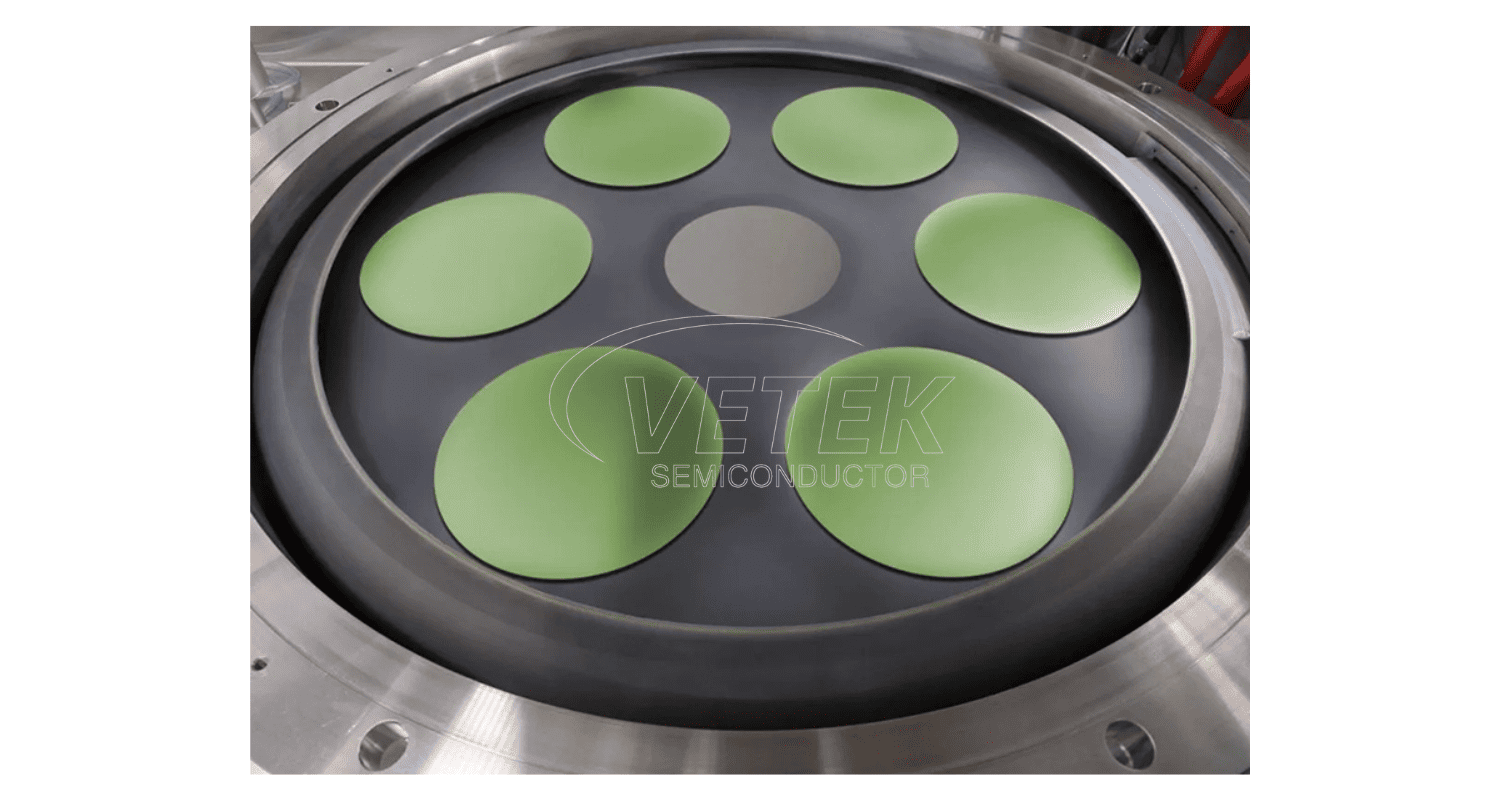

In calidum-Wall planetarium CVD ratio, cum planetarum dispositio ad basis, est propria per incrementum multiplici wafers in uno fornacem et excelsum output efficientiam. Repraesentativas exempla sunt aixg5wwc (8x150mm) et G10-sic (IX × 150mm aut VI × 200mm) series epitaxial apparatu of aixtron Germaniae.

Secundum AXTRON scriptor officialis fama, in VI-inch 4H-sic epitaxial laganum products cum crassitudine 10μm produci per G10 epitaxial fornacem potest stabiliter stabiliter consequi in sequentibus Indicatores: Inter-Wafer II%, Inter-Wafer Doping Deputing Doping concentration non-uniformitatem

Usque ad hoc genus exemplar est raro usus a domesticis users, et batch productio data est insufficiens, quod est quaedam extensura restringit eius ipsum application. In addition, debitum ad altum technica claustra ex multi-lagae epitaxial fornaces in terms of temperatus agro et fluxus agro imperium, in progressionem similes domesticis et non est adhuc in investigationis et VIII pollicis et non est in Tac et non solum in coating.

Quasi calidum murum vertical CVD ratio maxime rotat ad altum celeritate per externa mechanica auxilium. Et proprium est quod crassitudine viscosis iacuit efficacius reducitur per inferiorem reactionem thalamum pressura, ita augendae epitaxial incrementum rate. Eodem tempore, quod motus non habet superius murum in quo partes possunt deponi et non facile ad procidens obiecta. Is est inhaerens utilitatem in defectu imperium. Repraesentativas exempla sunt unum, laganum epitaxial furnas epireevos6 et epireVIS8 de Japan scriptor Nuflare.

Secundum ad Nuflare, incrementum rate de epirevos6 fabrica potest pervenire plus quam 50μm / h, et superficiem defectum densitas epitaxial lagae potest regi infra 0.1cm, ²; In terms of uniformitas potestate, Nuflare engineer Yoshiaki Daigo nuntiavit intra-wafer uniformitatem eventus a 10μm densalis6 VI-inch epitaxial lagam grown usura epirevos6 et intra-uniforming I% et 2,6% respectively.we providing I% et 2,6, et intra-uniforment, sicut I% et concentration non-uniforming ad I% et concentration.we.weSuperiori graphite cylindri.

In praesens, domesticis apparatu manufacturers ut core tertia generatione et jsg disposito et launched epitaxial apparatu cum similibus munera, sed non sunt usus in magna.

In generali, in tres genera apparatu habere sua proprietates et occupare quaedam foro participes in diversis applicationem necessitates:

Et calidum murum horizontalis CVD structuram features ultra-ieiunium incrementum rate, qualis et uniformitas, simplex apparatu operationem et sustentationem et mature magna-scale productio applications. Tamen, debitum ad unum-laganum genus et crebris sustentationem, productio efficientiam humilis; the warm wall planetary CVD generally adopts a 6 (piece) × 100 mm (4 inches) or 8 (piece) × 150 mm (6 inches) tray structure, which greatly improves the production efficiency of the equipment in terms of production capacity, but it is difficult to control the consistency of multiple pieces, and the production yield is still the biggest problem; Quod quasi-calidum murum vertical CVD habet complexu structuram, et qualis defectus imperium epitaxial lagam productio est optimum, quod requirit maxime dives apparatu sustentacionem et usum experientia.

Fast incrementum rate

simplex apparatu structuram et

Sustentationem convenient

Magna productio facultatem

princeps productio efficientiam

Bonum productum defectum imperium

Dum reactionem camera

victum exolvuntur

Complexu compages

Difficile est control

productum constantiam

Complex apparatu structuram,

difficile sustentationem

Representative

apparatu

manufacturers

Calidum Wall Horizontal CVD

Calidum Wall Planetarium CWD

Quasi-calidum Wall vertical CTD

Commoda

Incomages

Brevis sustentacionem cycle

Italia LPP, Japan Tel

Germania Aixtron

Iaponia Nuflare

With the continuous development of the industry, these three types of equipment will be iteratively optimized and upgraded in terms of structure, and the equipment configuration will become more and more perfect, playing an important role in matching the specifications of epitaxial wafers with different thicknesses and defect requirements.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |