QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Carbon sensitHabet optimum proprietatibus ut humilis scelerisque conductivity, parva specifica calor et bonum summus temperatus scelerisque stabilitatem. Saepe usus est ut a thermal velit materia in vacuo vel tutela atmosphaera et late in semiconductor agri. Tamen, in in environment cum temperatus superior quam CDL ℃, ipsum sensit erit cursim oxidized, unde in celeri exitium de materia. Processus environment of semiconductors est saepe altior quam CDL ° C, ita est maxime momenti ad amplio oxidatio resistentia carbo carbonis sensit.

Superficiem coating est idealis anti-oxidatio modum ad ipsum fibra products. Anti-oxidatio coatings includit metallum coatings, Ceramic coatings, vitrum coatings, etc inter Ceramic coatings, sic habet optimum summus temperatus oxidatio resistentia et bonum physica et chemical compatibility cum carbonis fibra products. Cum sic oxidized ad altum temperatus, in SIO2 generatae in superficiem potest implere rimas et aliis defectibus in coating et angustos in penetratio O2, faciens illud maxime vulgo coating materiam in carbonis fibra productum coating.

SIC coating paratus superficies ipsum sensit ipsum fibra eget vapor depositione. Post Ultrasonic Purgato, paratus Carbon sensit exaruit C ℃ ad tempus. Carboni sensit ad MC ℃ in vacuo fistulando camino cum AR sicut Globuli Gas et H2 ut carrier Gas, et calefacit trichloromethyl pergat in in reactionem thalamum per Bubbler modum. In depositione principii est ut sequitur:

Ch3Skick (G) → Sic (s) + 3HCl (G)

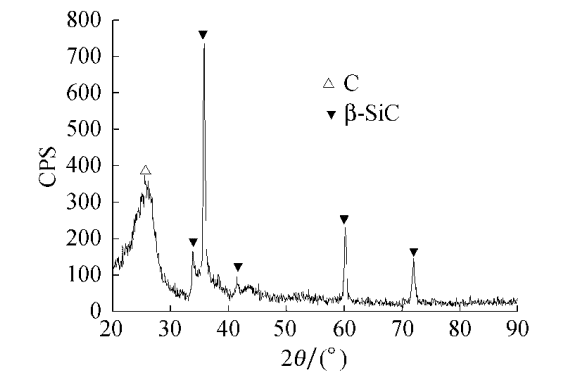

Nos solebat D8 Provance X-Ray Diffractometer (xrd) ad analyze phase compositionem of sic coating ipsum sensit. From the XRD spectrum of SiC coating carbon felt, as shown in Figure 1, there are three obvious diffraction peaks at 2θ=35.8°, 60.2°, and 72°, which correspond to the (111), (220), and (311) crystal planes of β-SiC, respectively. Potest videri, quod coating formatae super superficiem de ipsum sensit est β-sic.

Figura I xrd spectro de sic coating ipsum sensit

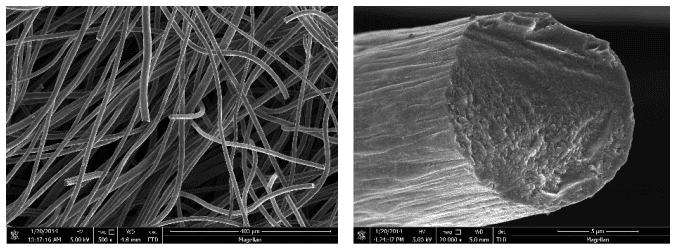

Nos usus est Magellanlanus CD scanning Electron microscope (Sem) ad servare microscopic morphologia de ipsum sensit ante et post coating. Sicut potest videri a Figura II, in carbon fibris intra originale ipsum sensit inaequaliter in crassitudine, cathartically distribuit, cum multitudine evacuat, et humilis altiore density (circiter 0,14 g / CM3). Praesentia multitudine evacuat et humilis density sunt pelagus rationes cur ipsum sensit potest adhiberi pro scelerisque velit materia. Sunt numerus striatus superficies carbonis fibris intra originale ipsum sensit per alimentorum fibra axem, quae adjuvat ad amplio ad vinculum vires inter coating et matricem.

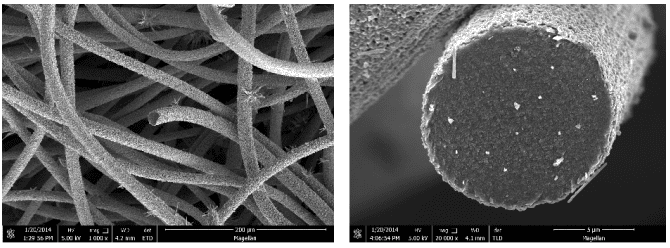

Ex comparatione figurarum II et III, quod potest videri quod carbo carbonis fibris intra coating ipsum sensit sunt operuit in sicci coatings. Et sic coatings formatae a parva particulas arcte reclinant, et coatings sunt uniformis et densa. Sunt arcte bonded ad ipsum alimentorum fibra Matrix, sine obvious Peling, rimas et foraminibus, et non est manifestum fregisset ad vinculum cum matrice.

Figura II De Morphologia de Carbon Sensit et Album Carbon Fibra finem antequam coating

Figura III De Morphologia de Carboni sensit et unum ipsum Fibra finem post coating

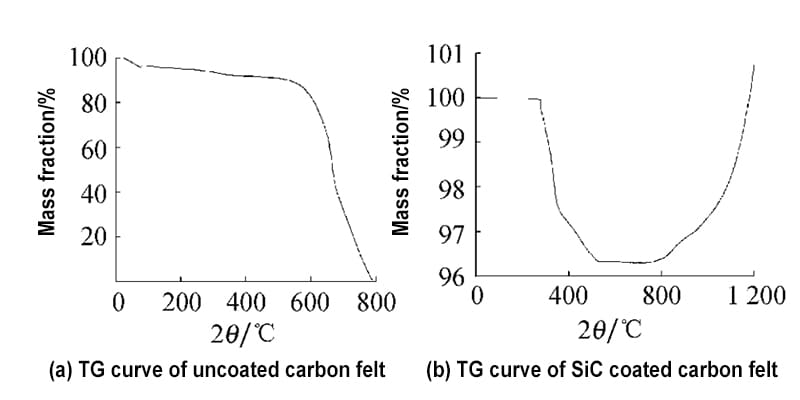

Nos conducted thermogravimetric analysis (TG) in Ordinarius ipsum sensit et sic coating ipsum sensit, respectively. Et calefactio rate erat X ℃ / min et aere fluunt rate XX ml / min. Figure 4 is the TG curve of carbon felt, where Figure 4a is the TG curve of uncoating carbon felt and Figure 4b is the TG curve of SiC coating carbon felt.It can be seen from Figure 4a that the uncoating carbon felt sample oxidizes slowly below about 600 ℃, and the oxidation rate is significantly accelerated after exceeding 600 ℃. In circiter DCCXC ℃, quod RELICTUM FRACTICUS de sample est 0, quod est quod dictum est totaliter oxidized.

Ut ostensum est in Figura 4b, cum Missam ipsum ipsum Missam cum temperatus sola locus temperatus ad CCLXXX ℃. In 280-345 ℃, in sample incipit ad oxidize paulatim et oxidatio rate est relative ieiunium. In 345-520 ℃, oxidatio progressus retardat. Circa DCCLX ℃ Missam damnum sample pervenit maximam, quod circa IV%. In 760-1200 ℃, ut temperatus resurget, et missa in sample incipit ad augendam. Hoc pondus lucrum. Hoc est quia sic in superficie carbonis alimentorum fibra est oxidized ad formare sio2 ad altum temperatus. Hoc reactionem est pondus lucrum reactionem, quae crescit massa specimen.

Comparet Figura 4A et Figura 4B, quod potest esse in DCCXC ℃, in Ordinarius Carbon sensit est totaliter oxidized, cum oxidation pondus damnum rate of IV de coating system sample est de SIC CIRCUMSPECTATIO SENTENTIA Sensit sample est de IV%. Cum temperatus ad MCC ℃, Missam de sicco coating ipsum sensit etiam crescit leviter debitum ad generationem sio2, significant, quod in sicco coating potest significantly amplio in altum temperatus aurei resistentia carbonis sensit.

Fig. IV TG curve Carbon Sensit

InSic coatingPrompositus in carbo feliciter a eget vapor depositione aequaliter distribuitur, continua, dense reclinant, et non manifesta foramina vel rimas. Et sic coating est arcte vinculum ad subiectum sine obvious hiatus. Is est valde fortis anti-oxidatio facultatem.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |