QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Nuper, in Nobel Nobel Prize in Nobel in Ridelmi Invivered in Roads in agro artificialis intelligentia. Et Research American Scientist John J. Hopfield et Canadian Scientist Galfridus E. Hinton utitur apparatus doctrina Tools ut providere novum insights in hodiernae complexu Physicis. Hoc factum non solum marcas est momenti milestone in artificialis intelligentia technology, sed etiam praecones in altum integrationem physicis et artificialis intelligentia.

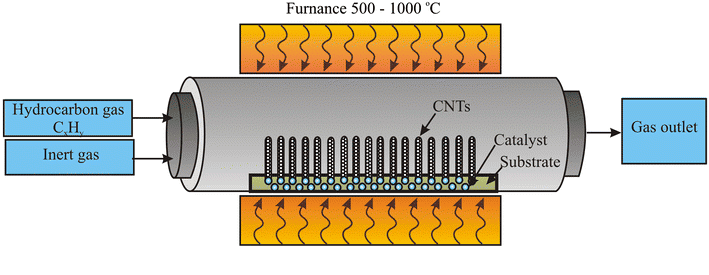

De significatione chemical vapor depositione (CVD) Technology in Physicis est multifaceted. Non solum est momenti materia praeparatio technology, sed etiam ludit a key munus in promovendi progressionem physicis investigationis et application. CVD technology potest pressius imperium incrementum materiae ad atomicus et molecular campester. Ut ostensum est in Figura I, hoc technology producit varietate summus perficientur tenuis films et Nanostructured materiae per chemica reagens gaseous vel vaporant substantiae in solidum superficiem generare solidum deposits1. Hoc est crucial in physicis ad intellectum et explorandum necessitudinem inter microstructure et macroscopic proprietatibus materiae, quia concedit scientists studere materiae cum specifica structuras et compositiones, et penitus intelligere corporis proprietatibus.

Secundo, CVD technology est a key technology ad parat variis officio tenuis films in semiconductor cogitationes. Exempli gratia, CVD potest ad crescere Silicon una crystallo epitaxial layers, III-v semiconductors ut Gallium Arsenide et II-VI semiconductor SICONDUCTOR Una Crystal Epitaxial films, et Sylycs Structures et ex Moderni etc. optoelectronic cogitationes. In addition, CVD technology etiam ludit an maximus munus in Physicis investigationis agros ut optical materiae, superconducting materiae et magnetica materiae. Per CVD technology, tenuis films cum specifica optical proprietatibus potest esse synthesized ad usum in optoelectronic cogitationes et optical sensoriis.

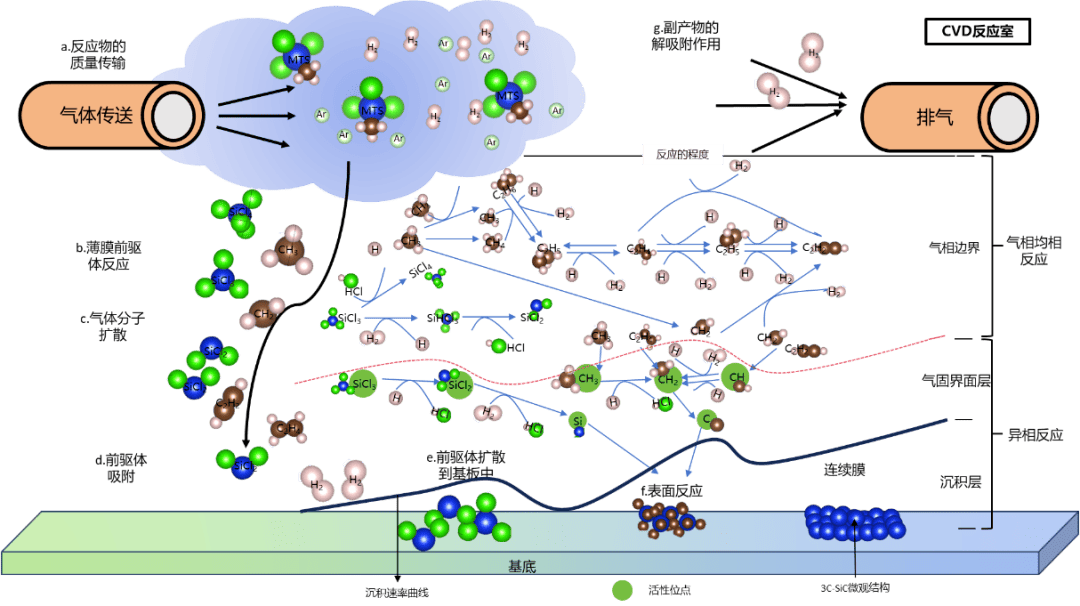

Figura I CVD reactionem transitum gradus

Simul CVD technology facies aliqua provocationes in practicum Applications ^ ut:

✔ Summus temperatus et princeps pressura condiciones: CVD solet necessitates ad ferri ex ad altum temperatus vel princeps pressura, quae fines genera materiae, quod potest esse et crescit industria consummatio et sumptus.

✔ Parameter sensibilitatemEt CVD processus est maxime sensitivo ad reactionem conditionibus, et parva mutationes afficit qualis est ultima uber.

✔ CVD ratio est universa: CVD processus est sensitivo ad terminum condiciones, habet magna incerta, et difficile ad control et repetere, quae ducunt ad difficultates in materia et progressionem.

Adversus haec difficultates, apparatus doctrina, ut potens notitia analysis instrumentum, ostensum est potentiale solvere problems in CVD agro. In his sunt exempla application of apparatus doctrina in CVD technology:

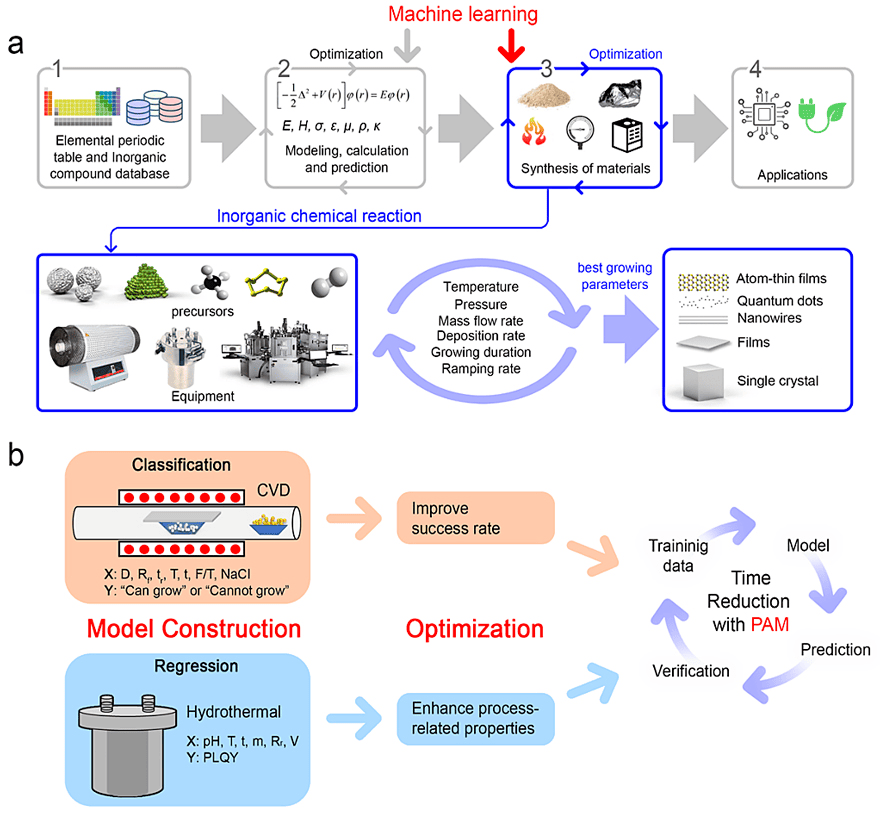

Using apparatus eruditatur algorithms, possumus discere a magnus moles experimentalem notitia et praedicere eventus CVD incrementum in diversis conditionibus, ita genset ad temperatio experimentalem parametri. Ut ostensum est in Figura II, in Research Team of Nanyang technica University in Singapore usus est genus algorithm in apparatus doctrina ad dirigendam CVD synthesis duo dimensiva materiae. Per analyzing mane experimentalem data, ut feliciter praedixit incrementum conditionibus de Molybdenum disulfide (Mos2), significantly improving ad experimentalem victoria rate et reducing numerus experimentalium.

Figura II Machina Doctrina Discipulus Material Synthesis

(A) in necessitate pars materialis investigationis et progressionem: materia synthesis.

(B) Classification Model iuvat chemical vapor depositione ad synthesize duo dimensiva materiae (top); Procunt Model Guides hydrothermal synthesis de sulphuris, nitrogen doped plororescent Quantum Dots (fundo).

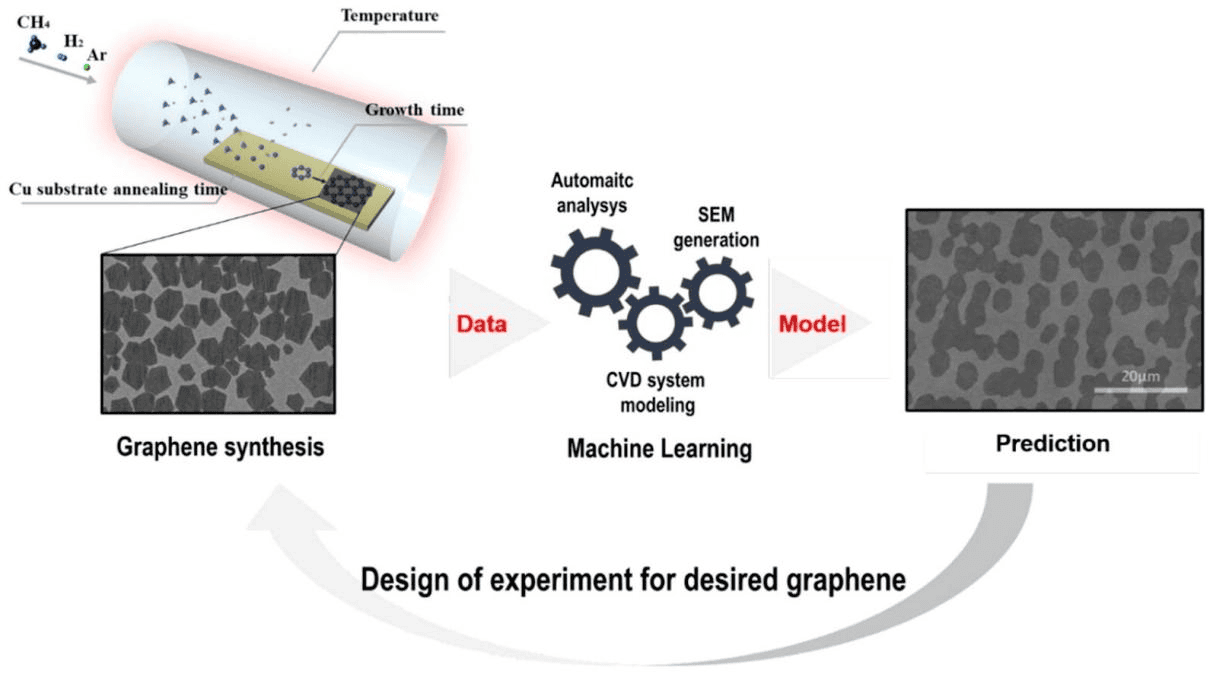

In alia studio (Figura III), machina doctrina est usus ad analyze incrementum exemplar est Grafene in CVD ratio. The size, coverage, domain density, and aspect ratio of graphene were automatically measured and analyzed by developing a region proposal convolutional neural network (R-CNN), and then surrogate models were developed using artificial neural networks (ANN) and support vector machines (SVM) to infer the correlation between CVD process variables and the measured specifications. Hoc approach potest simulate Graphene synthesis et determinare experimentalem condiciones ad synthesizing et desideravit morphologia magna grano magnitudine et humilis domain density, salute multum et cost² ³

Figura III Apparatus Doctrina Predicts Graphene incrementum Patterns in CVD Systems

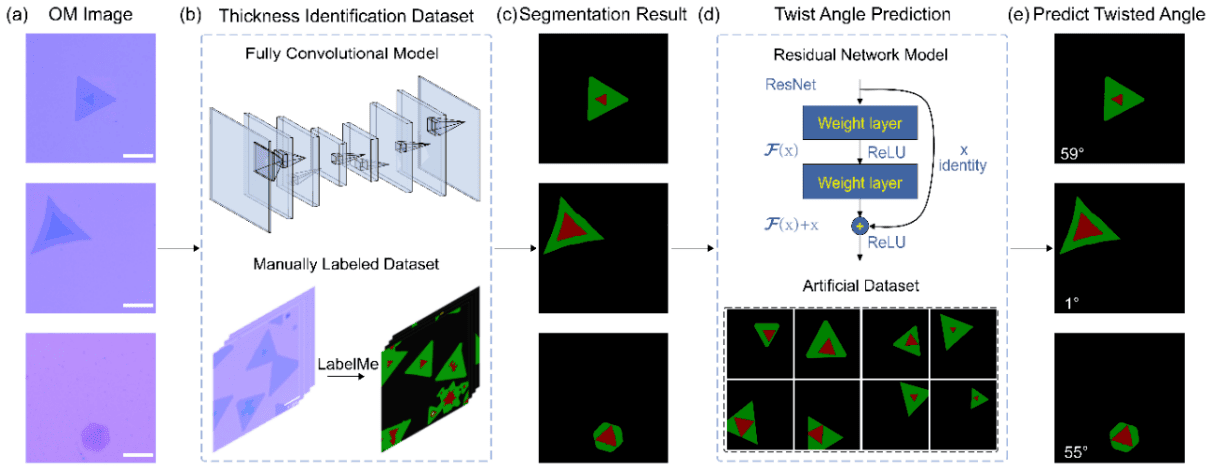

Machina doctrina potest ad develop automated systems ad monitor et adjust parametri in CVD processus in realis tempus ad consequi magis precise imperium et altius productio efficientiam. Ut ostensum est in Figura IV, a investigationis quadrigis ab Xidian University usus profunda doctrina superare difficultas de identifying gyrationis angulus CVD geminus-iacuit duo dimensiva materiae. Collectis colore spatium Mos2 paratus CVD et applicantur ad semantic semanticam convolutional neural network (CNN) ad verius et cito identify in crassitudine ad consequi accurate, et secundo rotatione angulus ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-rotationis angulus ad consequi accurate duplex-rotationis angulus ad consequi accurate duplex-rotationis angulus ad consequi accurate duplex-rotationis angulus ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-rotationis angulus ad consequi accurate duplex-rotationis angulo ad consequi accurate duplex-layer TMD materiae. Hoc modo non solum amplio efficientiam specimen sample idem, sed etiam providet novum paradigma ad applicationem abyssi doctrina in agro materiae scientiae4.

Figura IV altum doctrina modi identify the angulis duplici-iacuit duo dimensional materiae

References:

(I) Guo, Q.-m.; Qin, Z.-H. Development et applicationem vapor depositione technology in atomicus vestibulum. Acta Physica Sinica MMXXI, LXX (II), 028101-028101-28101-28115. Duo: 10,7498 / APs.70.20201436.

(II) Yi, k.; Liu, d.; Chen, x.; Yang, J.; Wei, d.; Liu, y.; Wei, D. Plasma-amplificata eget vapor depositione duorum dimensional materiae ad applications. Rationes of eget investigationis MMXXI, LIV (IV), 1011-1022. Doi: 10.1021 / ActsAccounts.0c00757.

(III) Hwang, G.; Kim, T.; Shin, J.; Shin, n.; Hwang, S. Machina Dearnings ad CVD Graphene Analysis: a measurement ad simulation Sem imaginibus. Journal of Industrial et Engineering Quaestiones MMXXI, CI, 430-444. Doi: https://Do.org/10.1016/j.jiec.201.05.031.

(IV) Hou, b.; Wu, J.; Qiu, D. Y. Unsupvised Doctrina singula Kohn-Foederatae: interpretationum repraesentationes et consequatur ad downstream praedictiones multorum, corporis effectus. MMXXIV; P II Arxiv: 2404.14601.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |