QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

InCrystal incrementum fornacemEst core apparatu ad crescente silicon carbide crystallis, sharing similibus cum Traditional Silicon cristallum incrementum Furnorum. Structuram non nimis complexu, praesertim constans in fornacis corporis, calefactio ratio, coil coil to coegi mechanism, vacuum acquisitionem et mensurae ratio, Gas copiam ratio, refrigerationem ratio, et imperium ratio. In scelerisque ager et processu conditionibus in fornacem determinare discrimine parametri qualis, magnitudine et electrica conductivity de Silicon carbide crystallis.

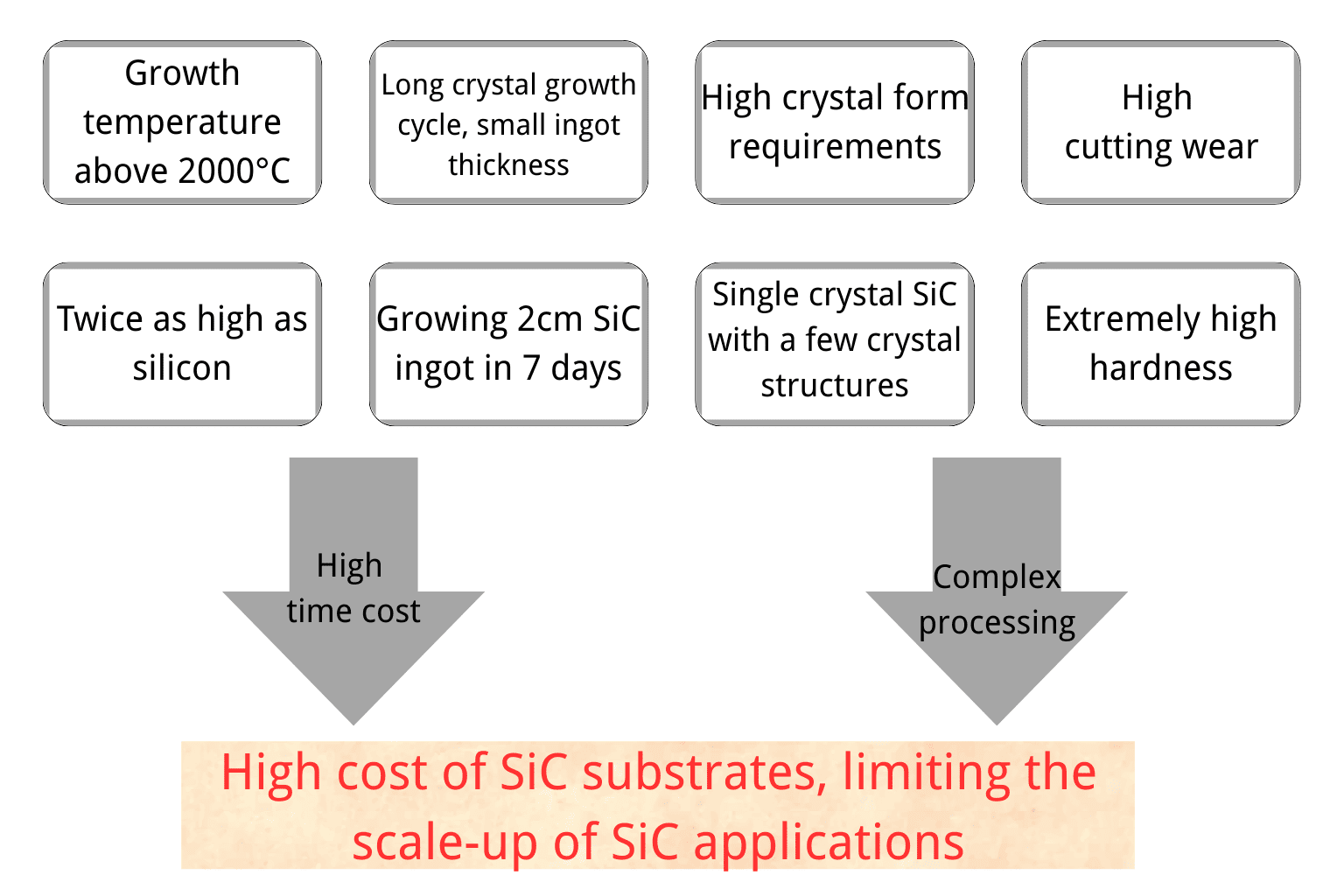

De una manu, in temperatus in Silicon carbide crystallum incrementum est maxime princeps et non monitored in real-vicis, ita primaria challenges iacere in processus ipsum.Pelagus challenges sunt ut sequitur:

(I) difficultas in scelerisque agro imperium: Cras in signatum summus temperatus camera est provocans et impotenti. Unlike traditional silicon-based solution-based direct-pull crystal growth equipment, which has high automation levels and allows for observable and adjustable growth processes, silicon carbide crystals grow in a sealed high-temperature environment above 2,000°C, and precise temperature control is required during production, making temperature control highly challenging;

(II) Crystalli structuram Imperium challenges: Quod incrementum processus est pronus ad defectuum ut microtubes, polymorphic inclusions, et CONVOLSUM, quae penitus et evolve per se.

Microtubes (MP) sunt per-genus defectus vndique magnitudine ex pluribus micrometris ad decem micrometris, et considerari interfectorem defectus cogitationes; Silicon carbide unum crystallis includit super CC diversis cristallum structurae, sed tantum a paucis crystal structurae (4h type) sunt idoneam ut semiconductor materiae ad productionem. Crystal structuram transformations durante incrementum potest ducere ad Polymorphic impuritatem defectus, ita precise imperium Silicon-ut-carbon Ratio, incrementum temperatus gradiente, crystallum incrementum rate, et gas fluxus / pressura parametri non requiritur;

Additionally, temperature gradients in the thermal field during silicon carbide single crystal growth result in primary internal stresses and induced defects such as dislocations (basal plane dislocations BPD, twist dislocations TSD, and edge dislocations TED), which affect the quality and performance of subsequent epitaxial layers and devices.

(III) difficultas in doping imperiumExterna impudicitiis oportet directivo directionem directionem doped Powerive Crystals;

(IV) tardus incrementum rate: Crystalli incrementum rate of Silicon carbide est maxime tardus. Dum Traditional Silicon materiae potest formare a cristallum virga in iustus III diebus, Silicon Carbide Crystal virgas requirere VII dies, inde in se output productionem efficientiam et graviter limited output.

In alia manu, in parametriSilicon carbide epitaxial incrementumSunt maxime restrictius, comprehendo apparatu signantes perficientur, reactionem aethereum pressura stabilitatem, precise imperium Gas introduction tempus, accurate Gas Ratio et stricte procuratio deposition temperatus. Praesertim sicut fabrica intentione ratings augere, difficultas moderantum core epitaxial laganum parametri significantly augetur. Praeterea, sicut crassitudo epitaxial layer augetur, ensuring uniformis resistentia dum maiorem crassitiem et reducere defectus densitas facta est alius major provocatione.

In electrica imperium system, summus praecisione integrationem sensoriis et actuators requiritur ut omnes parametri sunt verius et stabiliter regulatur. Optimization de potestate algorithms est etiam critica, ut oportet esse poterit ad adjust imperium strategies in real-vicis secundum feedback signals ad aptet ad variis mutationes in Silicon carbide epitaxial incrementum processus.

Clavis provocationes in sic substratum vestibulum:

Ex copia;Sic crystallum incrementum Furnorum, Ob factores ut diu apparatu certification cycles, princeps sumptibus consociata cum switching amet, et stabilitatem metus, domesticis amet nondum ad suppleret apparatu ad internationalis amet sic manufacturers. Inter eos, internationalis ducens silicon carbide manufacturers ut Wolfspeed, cohaeret, et Rohm praesertim uti crystallum incrementum apparatu developed et produci in-Germanica PVA Tepla et Japanese Nissin ARGENTUM Equipment Co., Ltd

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |