QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Oxidatio et diffusa Furnorum in variis agris ut semiconductor cogitationes, discreta cogitationes, optoelectronic cogitationes, potentia electronic cogitationes solis cellulis et magnis, integrated circuitu vestibulum. Sunt usi sunt pro processus inter diffusio, oxidatio, annealing, offering, et morticando lagana.

Vetek semiconductor est ducens manufacturer specialiter in productionem summus puritatis graphite, silicon carbide et quartz components in oxidatio et diffusio fornaces. Nos committitur providente summus qualitas fornace components pro semiconductor et photovoltaic industries, et in forefront of superficiem coating technology, ut CVD-sic, cvd-Tac, ut CVD-sic, cvd-Tac, ut CVD, etc.

● High Temperature resistentia (usque ad MDC ℃)

● optimum scelerisque conductivity et thermal stabilitatem

● bonum chemical corrosio resistentia

● humilis coefficiens scelerisque expansion

● princeps virtutis et duritia

● Long Service Vita

In oxidatio et diffusa Furnorum, ex praesentia altum temperatus et mordax vapores, multis components eget usum summus temperatus et corrosio, repugnant materiae, in quibus Silicon carbide (microform) est communiter electron. Et haec sunt commune Silicon Carbide components in oxidatio Furnorum et Diffusum Furnorum:

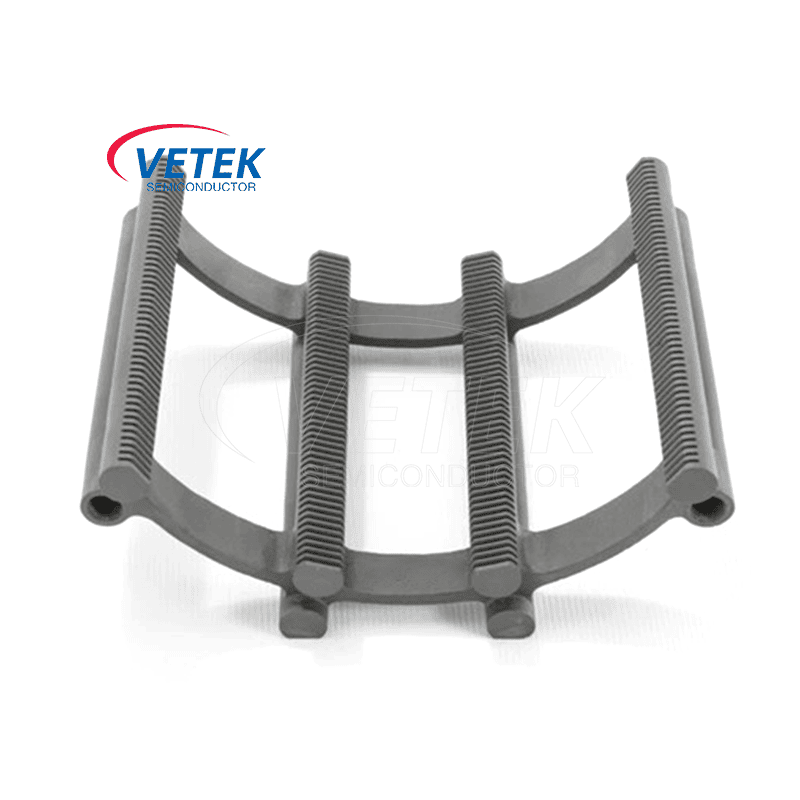

● Wafer navem

Silicon carbide laganum navi est continens usus ad portare Silicon lana, quae potest sustinere altum temperaturis et non agere cum Silicon wafers.

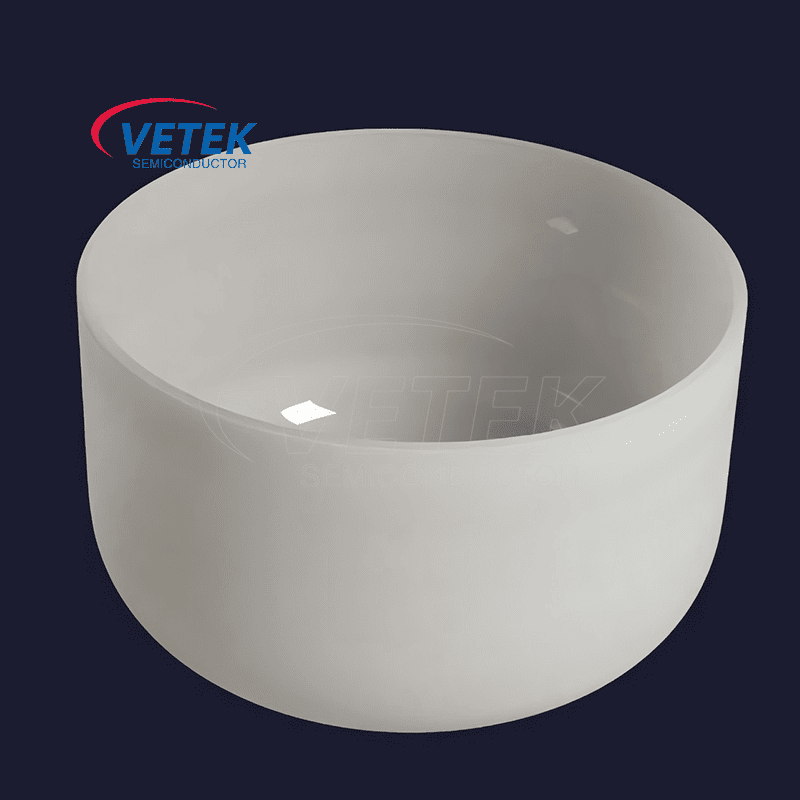

● fornacis tubo

Core in fornacem tubus est Core component de Diffusu fornacem, ad accommodare Silicon lana et control reactionem amet. Silicon carbide fornacem tubi habere optimum summus temperatus et corrosio resistentia perficientur.

● Baffle laminam

Ad moderari airflow et temperatus distribution intra fornacem

● Thermocouple praesidium tubi

Ad protegere temperatus mensuræ thermocouples ex recta contactus cum mordax vapores.

● cantilever paxillum

Silicon carbide cantilever paddles repugnant ad altum temperatus et corrosio et sunt ad onerariis Silicon naves vel quartz navibus portantes siliconica wafers in diffusionem fornacem tubulis.

● Gas injector

Ad introducendam reactionem Gas in fornacem, quod indiget repugnant ad altum temperatus et corrosio.

● navem carrier

Silicon Carbide Wafer navem carrier adhibetur figere et subsidium Silicon lana, quae ut commoda ut altus vires, corrosio resistentia et bonum structuram stabilitatem.

● fornacem ostium

Silicon carbide coatings vel components potest etiam esse in medio de fornace ostium.

● calefactio elementum

Silicon carbide calefacit elementa apta temperaturis, princeps virtutis et cito temperaturis ad M ℃.

● Sic liner

Ad protegendum interiorem murum fornacis tubulis, potest auxilium reducere damnum calor industria et sustinere dura ambitus ut altum temperatus et princeps pressura.

Shop high-performance Oxidation and Diffusion Furnace components at Veteksemicon—your trusted source for SiC-based thermal process solutions.

Veteksemicon supplies premium-grade silicon carbide (SiC) components designed specifically for oxidation and diffusion furnace systems in semiconductor manufacturing. These SiC parts exhibit excellent thermal shock resistance, high mechanical strength, and long-term dimensional stability in ultra-high-temperature and oxidizing environments. Ideal for process temperatures exceeding 1200°C, they are widely used in atmospheric and low-pressure diffusion systems, oxidation furnaces, and vertical thermal reactors.

Our product portfolio includes SiC cantilevers, boats, support rods, and tube liners, all engineered for precise wafer positioning and minimal particle contamination. The low thermal expansion coefficient of SiC helps maintain alignment across thermal cycles, while its chemical inertness ensures compatibility with O₂, N₂, H₂, and dopant gases. Whether for dry oxidation or dopant diffusion (e.g., phosphorus or boron), Veteksemicon’s diffusion furnace solutions enhance process stability, extend maintenance intervals, and support 200mm/300mm wafer formats.

For technical drawings, material datasheets, or quotation support, please visit Veteksemicon’s Oxidation and Diffusion Furnace product page or contact our application engineers.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |