QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

VeTek Semiconductor unica carbida tunicarum superiorum tutelam partium graphitarum in Processu SiC Epitaxy praebent pro processu exigendi materias semiconductores et compositas semiconductores. Effectus graphite extenditur ad vitam componentem, conservationem reactionis stoichiometriae, inhibitionis immunditiae migrationis ad epitaxiam et cristallum applicationum incrementum, inde in aucta cede et qualitate.

Nostra tantalum carbida (TaC) coatings fornacem criticam et reactorem partium in calidis calidis (usque ad 2200°C) custodiunt, ab ammoniacis calidis, hydrogenii, vaporibus et metallis liquefactis. VeTek Semiconductor amplis graphite processui et mensurae facultates habet ad occursum tuum requisitis nativus, ut mercedem fucatam vel plenam servitutem offerre possimus, cum machinarum peritiarum turma nostra parata est ad solutionem rectam pro te ac applicatione tua specifica. .

VeTek Semiconductor specialem TaC coatings variis componentibus et vectoribus praebere potest. Per VeTek Semiconductoris industriam efficiens processum ducens, TaC coating potest altam puritatem, caliditatem stabilitatem et altam chemicam resistentiam obtinere, ita productum qualitatem crystalli TaC/GaN) et EPl stratis emendans, et vitam reactoris criticae componentium amplificans.

Sic, GaN et AlN cristallum incrementum componentium cum vasculis, seminibus detentoribus, deflectentibus et sparguntur. Congregationes industriales inter elementa calefacientia resistentia, nozzles, annulos protegentes et adfixa aerea, GaN et SiC epitaxiales CVD reactor componentes inter laganum baiulum, scuta satelles, capita imbres, pileos et bases, MOCVD composita.

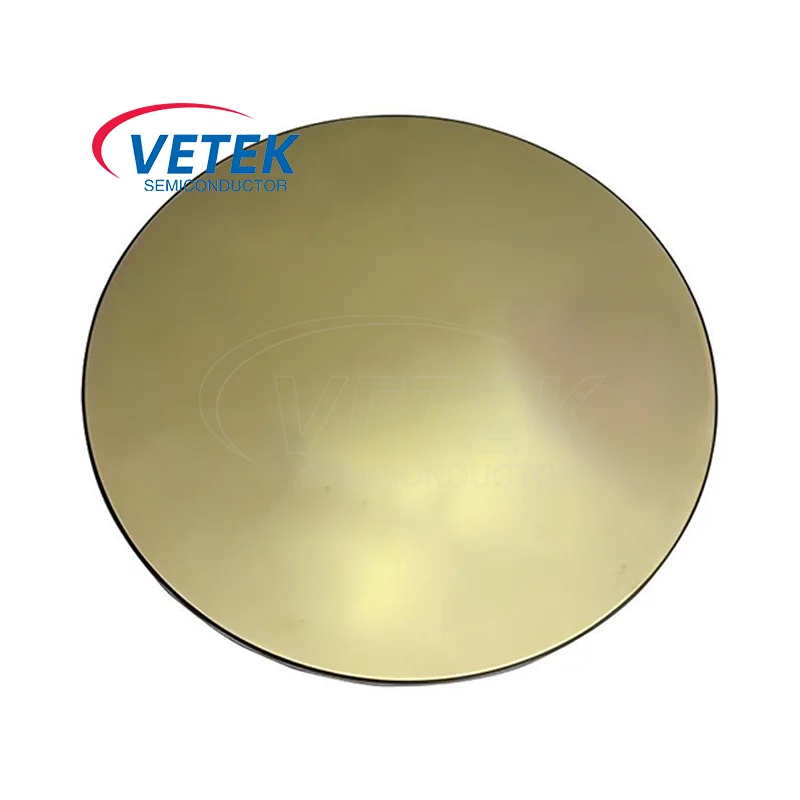

DUXERIT (Lucem Emittens Diode) Wafer Portitorem

● ALD(Semiconductor) Susceptor

● EPI Susceptor(SiC Epitaxy Process)

CVD TaC coating planetarium SiC epitaxial susceptor

CVD TaC coating planetarium SiC epitaxial susceptor  Tac Coated Ringo SiC Epitaxial Reactor

Tac Coated Ringo SiC Epitaxial Reactor  Tac Coated Three-petal Ring

Tac Coated Three-petal Ring  Tantalum Carbide Coated Halfmoon Pars LPE

Tantalum Carbide Coated Halfmoon Pars LPE

| Sic | Tac | |

| Principalis Features | Ultra puritatem, Excellens Plasma resistentia | Excellent caliditas stabilitatis (conformantia processus caliditas) |

| Puritas | >99.9999% | >99.9999% |

| Densitas (g / cm3) | 3.21 | 15 |

| Duritia (kg/mm2) | 2900-3300 | 6.7-7.2 |

| Resistentia [Ωcm] | 0.1-15,000 | <1 |

| Scelerisque conductivity (W/m-K) | 200-360 | 22 |

| Coefficiens scelerisque expansion (X "-6/℃) | 4.5-5 | 6.3 |

| Applicationem | Semiconductor Equipment Ceramic fig (Focus Ring, Shower Head, Dummy Wafer) | Sic Unius crystalli incrementum, Epi, UV partes DUXERIT Equipment |

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |