QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

De background estSIC

Silicon Carbide (SIC)Est momenti summus finis praecisione semiconductor materia. Ob eius bonum summus temperatus resistentia, corrosio resistentia, gerunt resistentia, summus temperatus mechanica proprietatibus, oxidation resistentia et alia characteres, quod est lata application spatio in altus-tech, quod est lata application spatio in altum, nationalibus et spatio technology, nationalibus defensionem et spatio technology, nationalibus defensionem et spatio technology, nationalibus defensionem et spatio technology, nationalibus et spatio technology.

Usque, quam CCSic crystal structuraesunt confirmata, pelagus genera sunt hexagonal (2h-sic, 4h-sic, 6h-sic) et cubica 3c-sic. Inter eos, et ex equiaxed structural notas 3C-sic determinare quod genus pulveris habet melius naturalis sphericity et densa stacking characteres quam α-sic, ita habet melius perficientur in casu et alias. In praesenti, variis causis duci ad defectum optimum perficientur 3C-sic novum materiae ad consequi magna-scale industrialis applications.

Inter plures sic polytypes, 3C-sic est solum cubica polytype, etiam quae β-sic. In hoc crystal structuram, si et C atoms in cancellos in unum-ad-unam Rationem, et singulis atom circumdatur quatuor heterogenea atomos formatam tetrahedral structuram unit fortis vincula. Structural pluma ex 3C-sic est quod si-c diatomic stratis saepe disposita in ordine ABC-ABC- ... et quisque unit cellulam habet tres tale drystomic stratis, quae dicitur C3 repraesentativum; Et crystal structuram de 3C-sic ostenditur in figura infra:

Currently, Silicon (SI) est maxime communiter semiconductor materia in potentia cogitationes. Tamen, debitum ad perficientur SI, Silicon-fundatur potentia cogitationes sunt limited. Comparari cum 4h-sic et 6h-sic, 3c-sic habet summum locus temperatus theoretical electronic mobilitatem (M cm · V-1QUOD-1), Et habet magis commoda in mos fabrica applications. In eodem tempore, 3C-sic etiam habet optimum proprietatibus ut alte naufragii intentione, bonum scelerisque conductivity, princeps duritia, lata bandgap, altum temperatus resistentia, et radialis resistentia.

Ideo non habet magnam potentiale in electronics, optoelectronics, sensoriis, et applications sub extrema condiciones, promovendos progressionem et innovation of related technologiae, et ostendens wide application potential in multis agros:

Primo, praesertim in altum intentione, altum frequency et altum temperatus environments, princeps naufragii intentione et excelsum electronicam mobilitatem 3C-sic facere idealis electionis est ad opitulatur potentia cogitationes ut mosfet.

Secundo: applicationem 3C-sic in Nanoelecteleronics et microelectromechanical systems (mems) beneficia ex suo compatibility cum Silicon technology, permittens fabricare de Nanokelections ut NanoelectRonics et NanoelectRomechanical cogitationes.

Tertio, sicut lata bandgap semiconductor materia, 3c-sic apta fabricare de hyacintho lux-emittens Diodes (LEDs). Et applicationem in luminatione, ostentationem technology et lasers habet attrahitur operam ex eius princeps luminosum efficientiam et securus doping [IX]. Quartum, simul, 3C-sic adhibetur ad fabricare positus-sensitivo detectors, praesertim laser punctum positus-sensitive detectors secundum laser photovoltaic effectus, quae ostendunt princeps sensus sub Nulla Bias conditionibus et idoneam sub Nulla Bias Conditionibus et idoneam sub Nulla Bias Conditionibus et idoneam sub Nulla Bias Conditions et idoneam sub Nulla Bias Conditionibus et idoneam sub Nulla Bias Conditionibus et idoneam sub Nulla Bias Conditionibus et idoneam sub Nuler Bias Conditions et idoneam sub Nulla Bias Conditionibus et idoneam sub Nulla Bias Conditions et in Certa.

Praeparatio modum 3C sic hETEROEPITAXY

The main growth methods of 3C-SiC heteroepitaxial include chemical vapor deposition (CVD), sublimation epitaxy (SE), liquid phase epitaxy (LPE), molecular beam epitaxy (MBE), magnetron sputtering, etc. CVD is the preferred method for 3C-SiC epitaxy due to its controllability and adaptability (such as temperature, gas flow, Time pressura et reactionem tempus, quod potest optimize qualis est epitaxial layer).

Chemical vapor deposition (CVD): A compound gas containing Si and C elements is passed into the reaction chamber, heated and decomposed at high temperature, and then Si atoms and C atoms are precipitated onto the Si substrate, or 6H-SiC, 15R-SiC, 4H-SiC substrate. Temperatus huius reactionem plerumque inter 1300-1500 ℃. Common SIH4 SIH4, TCS, MTS, etc., et C fontes sunt maxime C2H4, c3h8, etc., et H2 adhibetur ut tabellarius Gas.

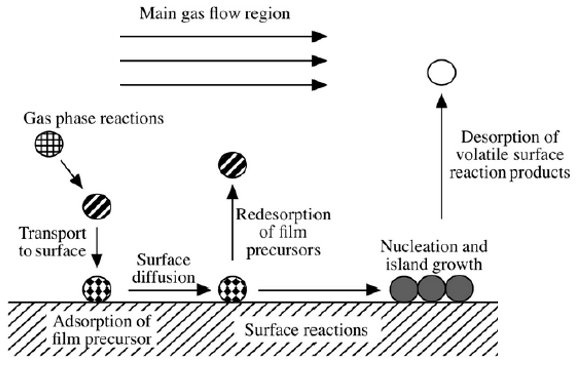

In incrementum processus maxime includit sequenti gradibus:

I. In Gas tempus reactionem fons transferatur in pelagus Gas influunt ad depositionem zone.

II. In Gas tempus reactionem occurrit in terminus iacuit ad generate tenuis film praecursores et byproducts.

III. Praecipitatio, aporption et elit processus praecursoris.

IV. ADSOMBED ADOME migrare et dulcemque in subiecto superficiem.

V. ADSORBED ETOMED nucleate et crescere in subiecto superficiem.

VI. Missam onerariam de vastum Gas post reactionem in pelagus Gas fluxus zona et sumitur ex reactionem cubiculum.

Per continuum technological progressus et in-profundum mechanism investigationis, 3c-sic heteroepitaxial technology expectat ludere a magis partes in semiconductor industria et promovere progressionem summus efficientia electronic cogitationes. Exempli gratia, in celeri incrementum summus qualitas densissima film 3C-sic est clavis ad occurrens necessitates altus-voltage cogitationes. Praeterea research opus est vincere statera inter incrementum rate et materiam uniformitatem; Combined cum application of 3C-sic in heterogenea structurae ut sic / Gan, explorandum potential applications in novus cogitationes ut potentia electronics, optoelectronic integration et quantum notitia dispensando.

Deals Semiconductor providet 3CSic coatingDe diversis products, ut summus puritas graphite et summus puritas Silicon carbide. Cum plus quam XX annis R & D expertus, nostra societas selects altus matching materiae, utSi Epi susceptor, SIC epitaxial susceptor, Gan in Si epi susceptator, etc., quod ludere an maximus munus in epitaxial iacuit productio processus.

Si vos have ullus inquisitione aut opus additional details, placere non dubitant ad adepto in tactus nobiscum.

Vulgus / whatsapp: + 86-180 (VI) CMXXII DCCLII

Email: Anny@veteksemi.com

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |