QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Praeparatio summus qualis Silicon carbide epitaxy pendeat provectus technology et apparatu et apparatu accessiones. In praesens, maxime late usus Silicon carbide epitaxy incrementum modum est eget vapor depositione (cvd). Is est commoda de praecise imperium epitaxial film crassitiem et doping concentration, paucioribus defectibus, modica incrementum rate, automatic processus imperium, etc., et certa technology quod est prospere applicari commercium.

Silicon Carbide CVD epitaxy plerumque adoptat calidum murum aut calidum Wall CVD apparatu, quod ensures continuatio epitaxy stratum 4h crystallino sic in altum incrementum temperatus et in altum, ut in Aeris, et in ARMENTUM STRATUM STRATURE AUCTORUM STRUCTRUS AUGUS ARGENTUM STRATUM STRATURE AUCTORUM Structure reactor.

Sunt tres principalis Indicatores ad qualis est sic epitaxial fornacem, primo est epitaxial augmentum perficientur, inter crassitiem uniformitatem, doping uniformitatem, rate et incrementum rate; Secundum est temperatus perficientur in apparatu se, comprehendo calefactio / refrigerationem rate, maximum temperatus, temperies uniformitatem; Denique sumptus perficientur apparatu se, comprehendo pretium et facultatem unius unitas.

Hot Wall Horizontal CVD (Typical Model Pe1o6 of LPE Company), calidum Wall Planetary CVD (typical Model Axtron G5WWC / G10 EPITIDEXIUS Technical Solutions, quae sunt in commercial applications in hoc scaena. Tria technica cogitationes etiam proprietates potest electus secundum demanda. Structura eorum ostenditur quod sequitur:

Downstream Nulla

Pelagus Nulla superius

Superius helfmoon

Vittream Nulla

Transitus pars II

Transitus pars I

Externum Aeris COLLUM

Tapered Snorkel

Exterus Argon Gas COLLUM

Argon Gas COLLUM

Wafer firmamentum laminam

Centro

Central Central

Donec Donec Cover

Downstream ius praesidium operimentum

Vimsteam reliquit Donec Cover

Vittream ius praesidium operimentum

Latus murum

Graphite Annuli

SENTATUS

Supporting sensit

Contactus obstructionum

Gas outlet cylindri

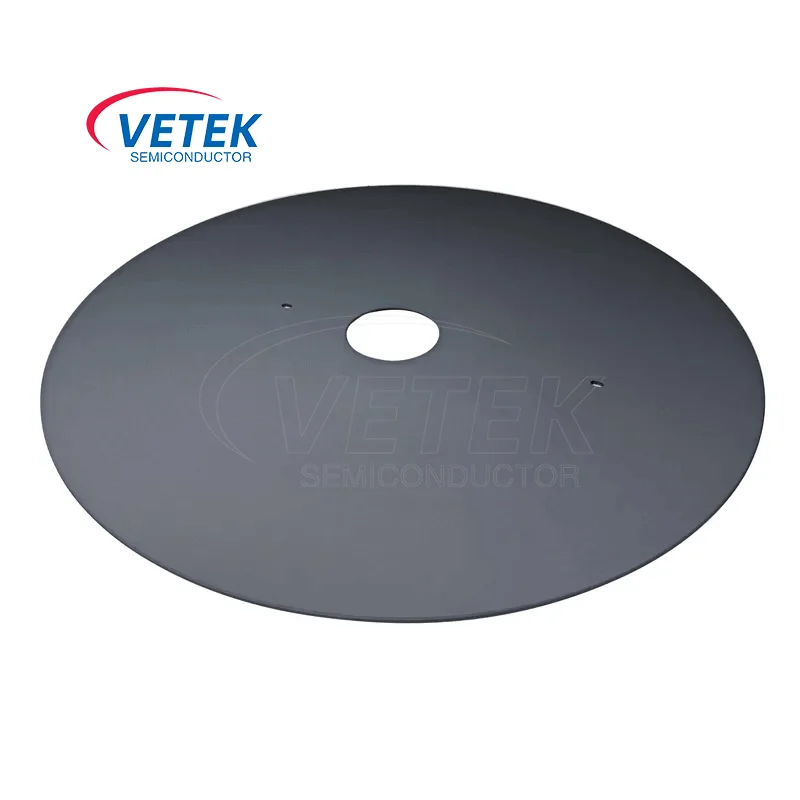

Sic coating planetarium orbis & Tac tulerunt planetarium orbis

Nuflare (Japan): Haec societas praebet Dual-cubiculum verticalis Furnaces quod conferre ad augeri productio cedat. Et apparatu features summus celeritas gyrationis ad M reveticula per minute, quae est altus prodest epitaxial uniformitatem. Praeterea, airflow directionem differt ab aliis apparatu, quod directe deorsum, ita obscuratis generatio particulas et reducendo probabilitatem particula procidens onto ad lagana. Nos providere core sic laqueus graphite components hoc apparatu.

Ut a elit de sic epitaxial apparatu components, Vetisk Semiconductor est committitur providing customers cum altus-qualitas coating components ut suscipio prospere exsequendam sic epitaxy.

Veteksemicon silicon carbide epitaxy is your advanced procurement option for producing high-performance 4H-SiC and 6H-SiC epitaxial layers used in wide bandgap semiconductor devices. SiC epitaxy enables the formation of defect-controlled, dopant-engineered epitaxial layers critical for high-power, high-frequency, and high-temperature electronic devices.

Our offering includes specialized components such as SiC epitaxial susceptors, SiC-coated wafer holders, and epitaxy process rings, tailored for use in horizontal and vertical MOCVD and CVD reactors, including platforms by Veeco, Aixtron, and LPE. Veteksemicon’s parts are coated with high-purity CVD SiC, ensuring chemical compatibility, temperature uniformity, and minimal contamination during epitaxial layer growth.

Silicon carbide epitaxy is essential for fabricating power MOSFETs, IGBTs, and RF components, particularly in automotive, energy, and aerospace applications. The epitaxial process requires extremely precise control over doping concentration, layer thickness, and crystallographic orientation, which is why substrate compatibility and thermal stability of reactor parts are critical.

Relevant terms in this category include 4H-SiC epitaxial wafer, low-defect-density epitaxy, SiC epi-ready substrates, and wide bandgap semiconductors. Veteksemicon supports both research-scale and volume production needs with stable, repeatable, and thermally robust component solutions.

To learn more about our silicon carbide epitaxy support materials, visit the Veteksemicon product detail page or contact us for detailed specifications and engineering support.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |