QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Tantalum Carbide (Tac) Ceramic materia habet liquescens punctum usque ad MMMDCCCLXXX ℃ et compositis cum altum liquescens punctum et bonum eget stabilitatem. Potest ponere firmum perficientur in altum temperatus environments. In addition, etiam habet altum temperatus resistentia, chemical corrosio resistentia, et bonum eget et mechanica compatibility cum carbon materiae, faciens idealis graphite substrati tutela coating materia.

Basic corporis proprietatibus Tac coating

Densitas

14.3 (G / CM³)

Specifica emissivity

0.3

Thermal expansion coefficient

6.3 * X-6/ K

Duritia (HK)

MM HK

Resistentia

I × 10-5 Ohm * cm

Scelerisque stabilitatem

Graphite magnitudine mutationes

-10 ~ -20um

CONGRESSUS

≥20um typical valorem (35um ± 10um)

Scelerisque conductivity

9-22 (W / M · K)

Tantalum carbide coatingPotest efficaciter protegat Graphite components ex effectis calidum ammonia, hydrogenii, Silicon vapor et conflatile metallum in dura usage environents, significantly extendendo ministerium vitae graphite components et suppressis in migrationem impudicitia in graphite et suppressis in migrationem impudicitia in graphite et suppressis in migrationem impudicitia in Graphite et suppressing in migrationem impudicitiis in Graphite et suppressing in migrationem impudicitia in Graphiteepitaxialetcrystal incrementum.

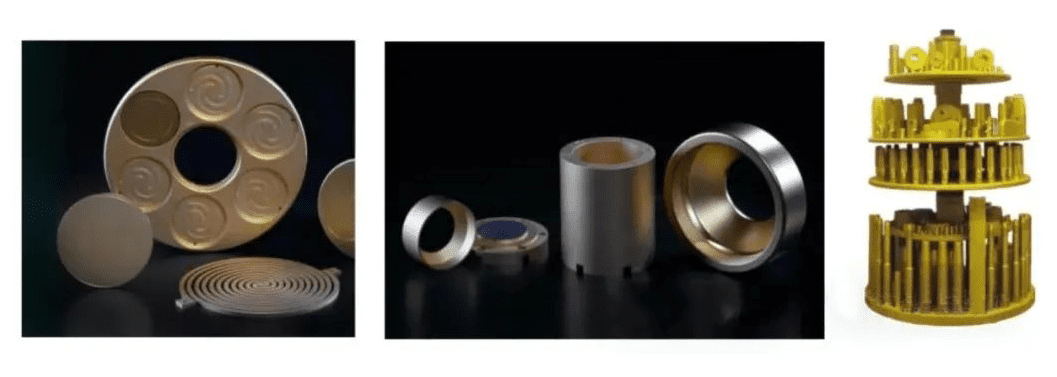

Figura I. Commune Tantalum Carbide iactaret components

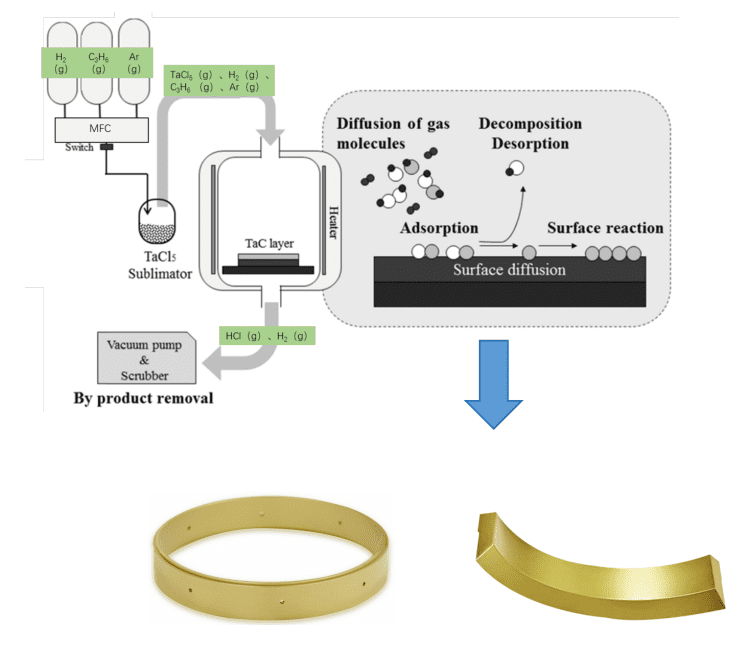

Chemical vapor depositione (cvd) est maxime mature et meliorem modum ad producendo Tac coatings in Graphite superficierum.

Using Tacl5 et propylene ut ipsum et Tantalum fontes respectively, et Argon ut carrier Gas, in altum temperatus vaporized Tacl5 vapor introducitur in reactionem thalamum. At the target temperature and pressure, the precursor material vapor adsorbs on the surface of graphite, undergoing a series of complex chemical reactions such as decomposition and combination of carbon and tantalum sources, as well as a series of surface reactions such as diffusion and desorption of by-products of the precursor. Denique a densa tutela layer formatur super superficiem in graphite, quae protegit in graphite ex firmum existentia sub extrema environmental conditionibus et significantly expandit applicationem missionibus graphite materiae.

Figura II.Chemical vapor depositione (CVD) processus principium

Nam magis notitia de principiis et processum parare cvd Tac coating, placere ad articulum:Quam ut parare CVD Tac coating?

SemiconMaxime providet Tantalum Carbide Products: Tac dux Ring, Tac Tres Folio Annuli:Tac coating crucem, Tac coating rorous Graphite late usus est sic crystallum incrementum processus; Porae Graphite cum Tac tunicas, Tac Tacitus Rector circulum,Tac iactaret graphite laganum carrier, Tac coating susceptores:Planetaria susceptatorEt haec Tantalum carbide coating products sunt late inSic epitaxy processusetSic una crystallum incrementum processus.

![]()

Figura III.VetEk Semiconductor est maxime popular Tantalum carbide coating products

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |