QR code

De nobis

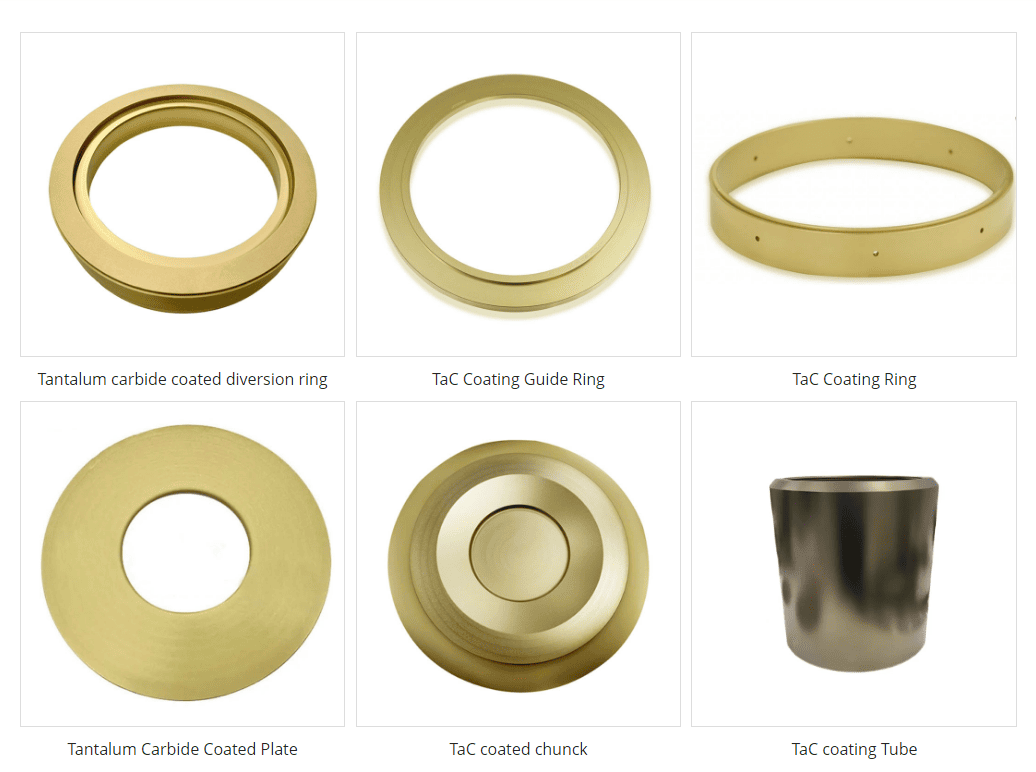

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

11 2024-12

11 2024-12  02 2024-12

02 2024-12  27 2024-11

27 2024-11  25 2024-11

25 2024-11  25 2024-11

25 2024-11  22 2024-11

22 2024-11