QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Tantalum Carbide (Tac)Est binarii compositis de tantalum (ta) et ipsum (c), cum eget formula plerumque expressit tacₓ (ubi x iugis a 0.4 ad I). Est classificatis sicut Refractius Ceramic materia cum praeclara duritia, summus temperatus stabilitatem et metallicum conductivity.

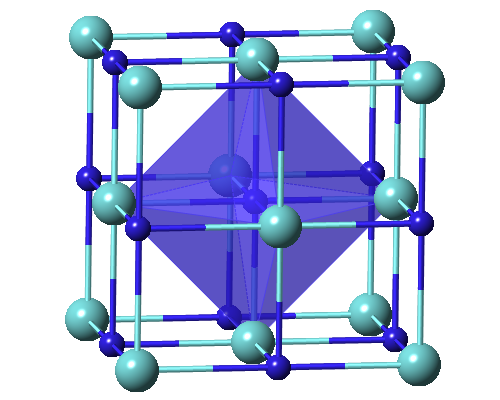

1.1 chemical compositionem et crystal structuram

Tantalum carbide est binarii Ceramic compositum composito ex Tantalum (ta) et ipsum (c).

Crystalli structuram est facies-sitas cubica (FCC), quod dat optimum duritiam et stabilitatem.

1,2 Bonding proprietatibus

Fortis coclent Bonding facit tantalum carbide maxime difficile et repugnant ad deformationem.

Tac habet maxime humilis diffusio coefficient et manet firmum etiam ad altum temperaturis.

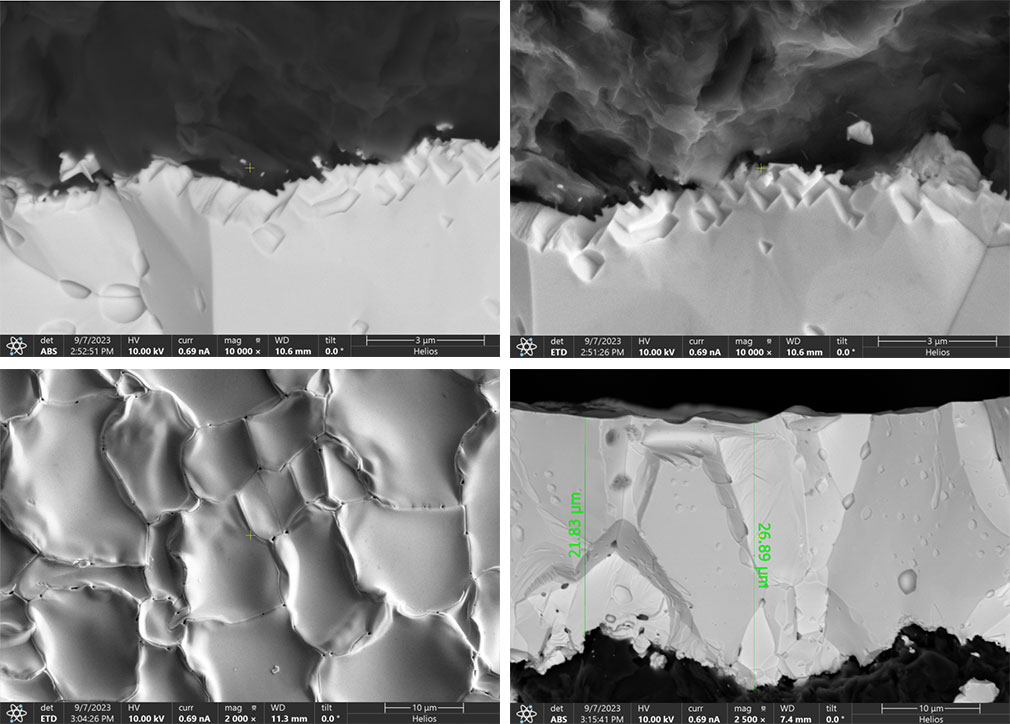

Tantalum carbide (Tac) coating in microscopic crucem-sectioni

|

Physica proprietatibus |

Values |

|

Densitas |

~ 14.3 g / CM³ |

|

Point liquescens |

~ 3,880 ° C (ipsum excelsum) |

|

Durities |

~ 9-10 Mohs (~ 2,000 Vickers) |

|

Electrical Conductivity |

Princeps (metallum, sicut) |

|

Scelerisque conductivity |

~ XXI w / m K |

|

FILII |

Valde repugnant oxidatio et corrosio |

2.1 Ultra-alta liquescens Point

Cum autem a parte liquescens 3,880 ° C, Tantalum carbide habet unum de summa liquescens puncta aliqua nota materia, unde in praeclara stabilitatem ad extrema temperaturis.

2.2 optimum duritiem

Cum a Mohs duritiam circiter 9-10, quod est prope adamantino et ideo late in gere, repugnans coatings.

2.3 bonum electrica conductivity

Dissimilis maxime Ceramic materiae, Tac habet altum metallum, sicut electrica conductivity, quae facit eam valuable pro applications in quadam electronic cogitationes.

2.4 corrosio et oxidatio resistentia

Tac est maxime repugnans ad acidum corrosio et maintains eius structural integritas in dura environments super diu tempora. Tamen Tac May oxidize ad Tantalum Pentoxide (Ta₂o₅) in aere supra 1,500 ° c.

3.1 Tantalum carbide coated partes

● CVD Tantalum Carbide coated susceptator: In used in siconductor epitaxy et altum temperatus processui.

● Tantalum carbide iactaret Graphite partes: In altum caliditas Furnaces et laganum processus gazophylacia. Exempla includit Tantalum carbide iactaret raro Graphite, quod significantly amplio processum efficientiam et crystal qualis per optimizing gas influunt per sic crystallus incrementum, reducendo scelerisque accentus, improving et inhibendo, immunditia corrosio resistentia, et inhibendo immunditia corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri corrosio resistentia, et inhibendo impuri.

● Tantalum carbide linivit gyrationis laminam: Veteksemicon Tac taac gyrationis laminam habet princeps puritatis compositionem cum minus quam 5ppm immunditia contentus et densa et uniformis structuram, quae est late in LPE EPI System, Aixtron Ratio, Veeco Ratio, TOX CVD Ratio, Veeco System, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio, Veeco Ratio, TSI Ratio. Systems, TSI systems.

● Tac iactaret calefacientis: De compositum de Tac coating scriptor maxime princeps liquescens punctum (~ MMMDCCCLXXX ° F) concedit eam ut operari ad ipsum altum temperaturis, praesertim in incrementum in metallum organicum eget vapor depositione (Mocvd) processus.

● Tantalum carbide iactaret cruce: CVD Tac tactas cruces saepe ludere a key munus in incrementum de sic una crystallis per Pvt.

3,2 secans instrumenta et gere, repugnans components

● Tantalum carbide iactaret carbide secans instrumenta: Improve tool vitae et machining accurate.

● Aerospace nozzles et calor clypeum: Provide praesidium in extrema calor et corrosive environments.

3,3 Tantalum Carbide High euismod Ceramic Products

● SpaceCraft scelerisque praesidio systems (TPS): Nam spatii et hypersonic vehicles.

● nuclei cibus coatings: Protect nuclei fuel pellets ex corrosio.

4,1 Tantalum carbide tunicas portarent (susceptóris) pro epitaxial processibus

Partes: Tantalum carbide coatings applicantur ad graphite carriers emendare scelerisque uniformitatem et eget stabilitatem in eget vapor depositione (CVD) et metallum-organicum eget vapor depositione (Mocvd) processibus.

Commodum, reducitur processus contaminationem et extenditur carrier vitae.

4.2 Etch et depositionem components

Wafer transitus annulos et clypeos: Tantalum carbide coating amplio ad diuturnitatem de Plasma Etch gazophylacia.

Commodum, sustinet infestantibus etching environments et reduces contaminant praecipitatio.

4,3 calefacit calefactio elementa

Applicationem in Sic CVD augmentum: Tantalum carbide iactaret calefacere elementa amplio stabilitatem et efficientiam de Silicon carbide (microform) wafer fabricam processus.

4.4 tutela coatings ad semiconductor vestibulum apparatu

Quid opus Tac coating? Semiconductor vestibulum involvit extrema temperaturis et mordax vapores, et Tantalum carbide coatings sunt effective in meliorem stabilitatem et vita apparatu.

Semicon est ducit manufacturer et elitTantalum carbide coatingMaterias ad semiconductor industria in Sinis. Nostra Main Products includit CVD Tantalum Carbide coated partes, SINERED TAC TACITRUM partibus pro Sic Crystalli incrementum aut Semiconductor epitaxy processibus. Veteksemicon est committitur esse innovator et ducem in Tantali carbide coating industria per continua R & D et technology iteration.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |