QR code

De nobis

Products

Nobis loquere

Phone

Fax

+86-579-87223657

E-mail

Oratio

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

1.The defectus density iam minuatur significantly

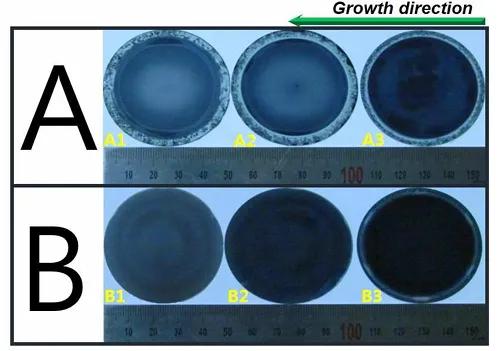

InTac coatingFere omnino excludit carbonis encapsulation phaenomenon per Isolating directum contactus inter graphite cruce et sic conflandum, significantly reducendo defectus densitas microtubes. Experimentalem notitia ostendere quod densitas microtube defectibus per ipsum coating in crystallum crevit in Tac iactaret cruces reducitur plus quam XC% comparari cum traditional graphite crucialibus. Crystal superficies est uniformiter convexa, et non est Polycrystallina structuram in extremis, cum Ordinarius graphite cruces saepe habent ore polycrystallization et crystallum tristitia et aliis defectibus.

II. In impuritas inhibitionis et puritate melius

Tac materia habet optimum chemical inertness ut si, C et n vapores et potest efficaciter prohibere impudicitiis ut NITROGENIUM in graphite a diffundens in cristallum. GDMS et Hall probat ostendere quod NITROGENIUM concentration in crystal iam minuatur plus quam L%, et resisto auctus est 2-3 temporibus, quod de traditional modum. Licet a Trace moles ta elementum erat incorporatus (nuclei proportionem <0.1%), in altiore totalis immunditia contentus in plus quam LXX%, significantly melior electrica proprietatibus in crystallo.

III. Crystal ERREPTIFICIUM et incrementum uniformitatem

Et Tac coating moderatur temperatus gradiente ad crystallum incrementum interface, enabling crystal ingot ad crescere in convexa curvam superficiem et homogenizing in ore augmentum rate, sic vitandum in traditional graphite phaenomenon in ore vitare in Traditional Graphite Phaenomenon in ore vitare in Traditional Graphite Phaenomeni fecit in ore vitare in Traditional Graphite Phaenomenon in ore vitare in Polycrystallization Phaenomenon in ore oclockoling in traditional GRAPHITE per ora, ita vitandum in Traditional Graphite Phaenomeni fecit in ore vitare in Traditional GRAPHITE PHATULUS. In ipsa mensuram ostendit quod diameter deviationis cristallum ingot crevit in Tac tunicas crustis est ≤2% et crystallum superficiem planationness (RMS) est melius a XL%.

|

Proprium |

Tac coating mechanism |

Impulsum in crystal incrementum |

|

Thermal conductivity & temperatus distribution |

De scelerislis conductivity (20-22 w / m k) est significantly inferior quam graphite (> C w / m · k) reducing radiale calor in incrementum et decrescendo a XXX% |

Improved temperatus ager uniformitatem, reducing cancellos exitum per scelerisque accentus et decrescentes defectus generation probabiliter |

|

Radiative calor damnum |

Superficiem emissivity (0.3-0.4) est inferior quam graphite (0.8-0.9), reducendo radiative calor damnum et permittens calorem redire ad fornacem corpus per convectio |

Enhanced scelerisque stabilitatem circa crystal, ducens ad plus uniformis c / si vapor concentration distribution et reducendo defectus per compositionis supersaturation |

|

Eget obice effectus |

Preverunt reactionem inter Graphite et si vapor ad altum temperaturis (si + c → sic), avoiding additional ipsum Source Release |

Maintains idealis c / si Ratio (1.0-1.2) in incrementum zona, suppressing inclusion defectus per ipsum supersaturation |

|

Material Type |

Temperatus resistentia |

Chemical inertness |

Mechanica fortitudinem |

Crystal defectus density |

Typical application missionibus |

|

Tac iactaret Graphite |

≥2600 ° C |

Non reactionem cum si / c vapor |

Mohs duritia 9-10, fortis scelerisque concursu resistentia |

|

Summus puritate 4h / 6h-sic una crystallum incrementum |

|

Nudum graphite |

≤2200 ° C |

Corroded per Si vapor releasing C |

Humilis vires prone ad crepuit |

10-50 cm⁻² |

Sumptus-effective Sic in SIC Power Fabrica |

|

Sic iactaret graphite |

≤1600 ° C |

Reacts cum formatam Sic₂ ad altum temperaturis |

Princeps duritiam et fragilis |

5-10 cm⁻² |

Packaging materiae ad medium temperatus semiconductors |

|

BN Crucible |

<2000k |

Releases N / B Impurisities |

Pauperem corrosio resistentia |

8-15 cm⁻² |

Epitaxial subiecta compositis semiconductors |

Et Tac coating habet effectum a comprehensive emendationem in qualis est Sic crystallis per triplici mechanism eget obice, scelerisque agro Optimization et interface regulat

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi Comitatus, Jinhua urbs, Zhejiang Provincia, China

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd. All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |